A cold storage equipment is a type of equipment used for storing perishable food items at low temperatures. These types of equipment prevent food spoilage, reduce waste, and ensure compliance with food safety regulations.

1. Equipment for Shipping Cold Products

When it comes to shipping cold products, having the right equipment is essential. From insulated containers to temperature-controlled trailers, there are many options to choose from to ensure that your products arrive at their destination in the best possible condition.

Revolutionizing the Frozen Product Management: Introducing the “Inline Pallet Spacer retrievers”

Top Industries has brought a game-changing innovation to the world of cold storage management with their Inline pallet and spacer retrievers. This automated solution is designed to handle frozen products with ease, replacing pallets and removing & inserting freezer spacers with unparalleled speed and efficiency.

The fastest solution of its kind in the world

The inline and spacer retrievers is the fastest solution of its kind in the world, making it an indispensable tool for any cold storage facility looking to streamline their operations. Its compact design allows it to be used in a variety of settings, while its versatility enables it to manage an array of different freezer spacer types.

Discover all the benefits with this solution

One of the most significant benefits of the inline and spacer retrievers is its ability to allow operators to insert freezer spacers, as well as remove them. No other solution on the market today can perform this crucial task, making Top Industries’ technology truly one of a kind.

People Also Ask

In cold storage facilities, crucial equipment includes refrigeration units, insulation, temperature monitoring systems, shelving, and forklifts. These tools are essential for maintaining a controlled temperature environment, ensuring product quality and safety.

To construct a cold storage facility, you’ll require a strategic location, robust refrigeration systems, insulation, precise temperature control, efficient storage racking, insulated doors, and a reliable HVAC system. These are essential components for building a successful cold storage facility

The cost of purchasing a cold storage facility can vary significantly based on factors like size, location, insulation, and equipment. Generally, prices can range from thousands to millions of dollars

Cold storage equipment must maintain temperatures typically between -10°C to -20°C (-4°F to -22°F) for frozen goods and between 0°C to 4°C (32°F to 39°F) for refrigerated items.

Save time and reduces risk of injury

In addition to its speed and versatility, the inline and spacer retrievers also saves time and money for operators by reducing the time required to manage frozen products. Furthermore, it also reduces the risk of injury to operators, providing an added level of safety in the workplace.

Summary of inline pallet and spacer retrievers

In conclusion, the inline and spacer retrievers from Top Industries is a must-have solution for any cold storage facility looking to improve their efficiency, speed, and safety. With its optimized design for search engines, this innovative product is set to revolutionize the world of frozen product management.

Revolutionize Your Cold Storage Operations with an Inline Pallet Inverter

An inline pallet inverter is a game-changer for any cold storage warehouse looking to improve efficiency and streamline operations. It allows for quick and easy insertion and removal of freezer spacers, which helps to optimize the flow of goods and reduce downtime. With its automated design, an inline pallet inverter can significantly speed up the process of storing and retrieving products, freeing up valuable time and resources for other tasks.

Enhancing Warehouse Safety with an Inline Pallet Inverter

In addition, an inline pallet inverter can also help to improve the safety of your operations. By automating the process of inserting and removing freezer spacers, you can reduce the risk of injury and increase the overall safety of your warehouse. With its reliable and efficient performance, an automatic pallet inverter is an investment that is sure to pay off in the long run,

Revolutionize Your Cold Storage Operations with an Inline Pallet Inverter

So if you’re looking to revolutionize your cold storage operations, consider investing in an inline pallet inverter. Whether you’re in the food and beverage industry, pharmaceuticals, or retail, this innovative piece of equipment can help to take your operations to the next level.

2. Equipment for Receiving Cold Products

Here’s a bulleted list of cold storage equipment:

- Pallet inverter

- Portable pallet inverter

- Pallet dispensers

- Plastic pallets

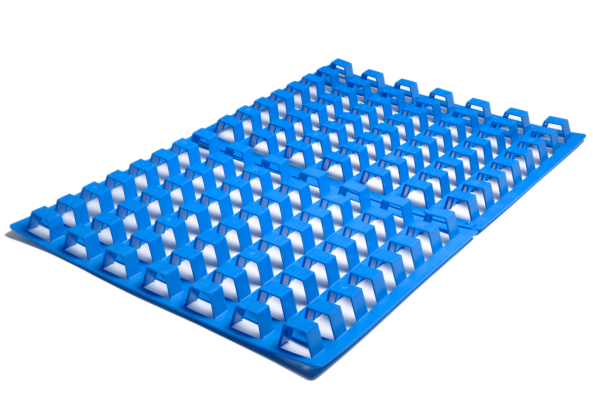

- Freezer spacers

- Freezer spacers removal machine

Receiving cold products is an essential part of the cold storage process, and having the right equipment can make a big difference in the efficiency and quality of your operations. From temperature-controlled docks to product handling equipment, there are many options to choose from to meet your specific needs.

Top Industries is revolutionizing the way cold storage facilities handle the intake of products with their cutting-edge equipment. With a focus on streamlining the process and reducing labor efforts, Top Industries is helping cold storage facilities increase their efficiency and productivity. By providing innovative labor-saving devices such as freezer spacers and inline pallet inverters, Top Industries is making it easier for workers to handle the chilly temperatures and maintain the temperature of the goods.

When it comes to properly storing cold products in a warehouse, Top Industries understands the importance of maintaining the temperature of the goods and the cleanliness of surfaces. With a wide range of equipment options to choose from, cold storage facilities can find the right tools to suit their specific needs. By choosing Top Industries, facilities can ensure that they are staying ahead of the competition and maximizing their efficiency.

Freezer Spacers

Freezer spacers play a crucial role in ensuring that cold storage facilities operate efficiently. These simple yet effective devices help to maintain the temperature of stored goods, prevent damage to products, and maximize storage space. With the right freezer spacers, facilities can ensure that their operations run smoothly and that their products remain in the best possible condition.

Maximizing Efficiency: Choosing the Right Freezer Spacers

When it comes to choosing freezer spacers, it is important to consider a number of factors, including the size and weight of the products being stored, the temperature requirements, and the amount of space available. In order to maximize efficiency, it is important to choose the right freezer spacers for the job.

Revolutionary Freezer Spacer Insertion and Removal Robotics: Introducing the Fastest and Most Versatile Freezer Spacer Removal System in the World

Cold storage facilities are facing a new challenge with the increasing demand for efficient and organized storage solutions. This is where the freezer spacer removal system comes in. This revolutionary machine, also known as the freezer spacer removal robot, is bringing a new level of innovation to cold storage facilities.

Unbeatable Speed and Compact Design: The Advantages of Freezer Spacer Removal System

One of the key strengths of this machine is its speed. With no other machine on the market that can match its speed, the freezer spacer removal system can handle a large number of spacers quickly and efficiently. Another advantage of this machine is its compact design, which makes it easy to maneuver in tight spaces and store when not in use.

Versatile and Unique: The Value of Freezer Spacer Removal System in Cold Storage Facilities

Moreover, the freezer spacer removal system is highly versatile. It can handle a wide range of freezer spacers with ease, making it a valuable addition to any cold storage facility. Another important factor is its ability to allow the operator to insert freezer spacers, not just remove them. There is no other solution in the world that can perform this task, making the freezer spacer removal system truly unique.

The Freezer Spacer Removal System: The Must-Have Solution for Improved Cold Storage

In conclusion, the freezer spacer removal system is the ideal solution for cold storage facilities looking for a fast, compact, and versatile machine that can handle a variety of spacers. Its innovative design, unmatched speed, and unparalleled versatility make it a must-have for any cold storage facility looking to improve its storage solutions.

Quality and Durability

Leading manufacturers are known for producing high-quality and durable cold storage equipment, ensuring that their products can withstand the demands of daily use and provide long-lasting performance. This is particularly important in industries where the products being stored are perishable and require consistent temperature control.

Customer Support

In addition to the quality and durability of the equipment, leading manufacturers also offer excellent customer support. This includes training and support for using the equipment, as well as maintenance and repair services to keep your equipment in good working order.

In conclusion, cold storage equipment is a critical component in a number of industries, and choosing the right equipment can make a big difference in the efficiency and success of your operations. From layout and flow of goods to product handling and inventory management, there are many factors to consider when selecting cold storage equipment. By choosing equipment from leading manufacturers and incorporating best practices for cold storage management, you can ensure that your operations are as efficient and effective as possible.

6. Cold Storage Equipment Layout

When it comes to designing a cold storage warehouse, it is essential to consider the layout and flow of goods. The right layout can increase efficiency, reduce handling time, and improve inventory control.

Importance of Proper Layout

A well-designed cold storage layout can make a big difference in the efficiency of your operations. Proper flow of goods can reduce the need for manual handling, minimize the risk of damage to products, and improve inventory control.

Key Considerations for Cold Storage Equipment Layout

When designing your cold storage warehouse, there are several key considerations to keep in mind, including space utilization, product flow, and accessibility to equipment and storage areas. It is also important to consider the type of products you will be storing, as well as the size and weight of your cold storage equipment.

Here are a few cold storage equipment

Selecting the right devices capable of removing or inserting the freezer spacers can ensure that products will be kept at a certain desired temperature during your handling process while also increasing productivity.

1. The Original Portable Pallet Inverter

Since pallets are always an integral part of all these Cold Storage Frozen Food warehouses, it is no surprise therefore those pallet retrievers will be on the list as one piece of equipment that you just cannot ignore.

Such equipment can help you to combine loads, remove freezer spacers, and safely exchange your pallets. This portable pallet inverter is an advanced cold food storage equipment

3. Challenges Facing Cold Storage Warehouse Industry

The cold storage warehouse industry is facing a number of challenges, from rising costs to increasing competition. From managing inventory to ensuring the safety and quality of products, it is essential for businesses to stay ahead of the curve.

Rising Costs

The cost of operating a cold storage warehouse can be significant, with rising costs for energy, labor, and equipment. Keeping costs under control requires careful planning, efficient operations, and the use of high-quality cold storage equipment.

Competition and Market Changes

The cold storage warehouse industry is highly competitive, with new players entering the market regularly. Staying ahead of the competition requires staying up-to-date with the latest industry trends and technology, and using the best cold storage equipment.

Cold Storage Management Best Practices

Effective cold storage management is essential for maximizing efficiency and maintaining the quality of your products. From maintaining the right temperature to tracking inventory, there are several best practices to keep in mind.

Maintaining the Right Temperature

Maintaining the right temperature is crucial for preserving the quality and safety of your products. This requires careful monitoring and control of the temperature, as well as regular maintenance and testing of your cold storage equipment.

Tracking Inventory

Tracking inventory is a critical aspect of cold storage management, as it allows you to keep track of your products, monitor usage, and make informed decisions about your operations. This can be done manually or with the help of inventory management software, depending on the size and complexity of your operations.

4. Changes in the Industry

The cold storage warehouse industry is constantly evolving, with new technologies and trends emerging regularly. Keeping up with these changes is essential for staying ahead of the competition and improving your operations.

Advancements in Technology: The Freezer Spacer Removal System by Top Industries Inc.

Advancements in technology have had a significant impact on the cold storage warehouse industry, from improving temperature control to enhancing inventory management. From using energy-efficient pallet tipper equipment to implementing advanced software solutions, staying up-to-date with the latest technology is essential for maximizing efficiency and competitiveness. And one company that is leading the charge in this area is Top Industries Inc. with their state-of-the-art “Freezer Spacer Removal System”.

The Freezer Spacer Removal System by Top Industries Inc. is a game-changer for any cold storage warehouse looking to improve efficiency and streamline operations. By automating the process of inserting and removing freezer spacers, the Freezer Spacer Removal System can significantly speed up the process of storing and retrieving products, freeing up valuable time and resources for other tasks. This innovative solution has the potential to revolutionize the way frozen foods are managed, providing a more efficient and safer process.

In addition, the Freezer Spacer Removal System is designed to be user-friendly, making it easy to integrate into any existing cold storage setup. The intuitive design and automated features help to eliminate the risk of human error, while the energy-efficient technology reduces the overall energy consumption of your warehouse. With its reliable and efficient performance, the Freezer Spacer Removal System is an investment that is sure to pay off in the long run.

So if you’re looking to stay ahead of the game and revolutionize your cold storage operations, consider the Freezer Spacer Removal System by Top Industries Inc. Whether you’re in the food and beverage industry, pharmaceuticals, or retail, this innovative piece of equipment can help to take your operations to the next level.

Industry Trends

The cold storage warehouse industry is also influenced by broader trends, such as sustainability and the move toward more environmentally-friendly practices. Keeping up with these trends and incorporating them into your operations can help to improve your reputation and increase customer loyalty.

5. Why Top Industries Inc?

Leading manufacturers understand the importance of having the best equipment for their operations, and that’s why they turn to Top Industries for their cold storage needs. With years of experience in the industry and a commitment to innovation, Top Industries offers a wide range of equipment options that can help manufacturers achieve their goals. From energy-efficient refrigeration units to automated inventory management systems, Top Industries has the right tools to meet the unique needs of each manufacturer.

In addition, Top Industries is dedicated to providing superior customer service, ensuring that their clients have access to the support they need to get the most out of their equipment. From installation to ongoing maintenance, Top Industries is there every step of the way, providing the expertise and support that manufacturers need to succeed.

When it comes to cold storage equipment, Top Industries is the go-to choice for leading manufacturers who want to stay ahead of the competition. With their commitment to quality, innovation, and customer satisfaction, manufacturers can trust Top Industries to provide the best equipment and support for their operations.

They are perfect for application on products that are frozen or temperature cautious like meat, poultry, seafood, vegetables, and more.

How this portable pallet inverter works?

When the clamp will be released from the top of the load then it will allow your product to glide away from your pallet or load table to enable quick, safe, and simple pallet transfer, replacement, or freezer blasting slat removal. Model designs may vary, but many of them may use a combination of components that can rotate stacks of products and pallets for making storage adjustments fast and easy.

Why is a versatile cold storage equipment?

They can also adjust based on the stack that you want to move. Then, they can slide below the stack and also above it and will tilt it back until you reach easily the pallets, freezer spacers, or products to make proper adjustments in the storage as needed.

Manual labour vs automatic machine

The alternatives to such cold food storage equipment are manual labor or using forklifts for which they are not designed. Both of these methods may take a much longer time and produce an unsafe environment. Upgrading from such a manual labor process can help improve your bottom line because the efficiency of your pallet retriever is something that cannot be matched by human hands.

You will also notice a similar improvement if you upgrade from navigating all these tasks with a forklift. Since there are always some uses for forklifts in all warehouses, this is one job that will be better suited for a pallet retriever.

These cold food storage equipment solutions can offer the most prominent pallet inverter machines loading all different types of shipments right from bags, and drums to boxes, cartons, and tins.

2. Freezer spacers/plastic pallets

These also play a major role in the industry of Cold Storage Frozen Food. Such freezer spacers are meant for minimizing product freeze time and also save on utility costs.

With such spacers, cold air can always move between product layers, resulting in dependable freezing for your complete pallet load.

How this cold storage equipement works?

As soon as the products reach a certain temperature, then you can remove the spacers between product stacks. Older pallets are generally made of wood and not plastic. While they may serve the same purpose, however, often plastic freezer spacers are more preferred, particularly for frozen food storage.

Wood is susceptible for rot, mold, and insects, and after a few years may break down and wear out as it is biodegradable. All such are concerns, particularly in the frozen food industry, as food contamination may ruin products and cause profit loss.

While the exact method of applying plastic wrap may differ based on what type of stretch wrapper you have, these equipment pieces are built for helping you wrap pallet loads quickly and also with additional tension on your plastic wrap, which can protect your food products from theft and damage.

Stretch wrappers may vary a lot in size, starting with portable units that are available to navigate large frozen food warehouses up to large, conveyorized models that can take up over 250 square feet.

How to choose the right Cold food storage equipment?

In order to understand which cold storage equipment is right for your business, our experts will ask you these following questions:

- How much space do you have

- Your maximum load sizes

- Your production speeds.

Several, options are available, offering you the chance to streamline your frozen food logistics. If you are considering a stretch wrapper to be an alternative to hand wrapping, then you are sure to notice a difference in your bottom line. Stretch wrappers can save time on your manual labor and also use at least 30% less film, thus offering you savings on your supplies.

Handling frozen product in cold storage warehouse

The demand for cold storage warehouse is continuously growing where automated 3-dimensional shuttle pallet storage, as well as retrieval systems, have become highly desirable solutions for the movement of pallets and storage in refrigerated and also deep-freeze warehouses. As the demand for chilled and frozen food products is quite high all over the world, it has created the need for more cold storage warehouses.

Discover the study on cold storage warehouses

A study done by the (International Association of Refrigerated Warehouses), shows that between 2014 and 2016, 210 million cubic feet of space of refrigerated area was added to North American warehouses, which represents a 2.3% annualized growth rate.

Another study of IARW in 2016 also revealed that refrigerated space of 1.7 billion cubic feet was added to warehouses from 2014 to 2016, hence the annualized growth rate was 4.2% of a cubic foot. The new offerings for the following food items continue to fuel further growth of a cold storage warehouse:

- Coin meat

- Seafood ready meals

- Dairy

- Fruits

- Vegetables

- Pizza

- Bakery

- Desserts

- Prepared pasta

- Prepared potato products

Globally, the sector of frozen foods is likely to grow at a compound annual growth rate of 5.2% between 2017 and 2023, as per the analysis conducted by several industry analysts. Also, at the same time, the growth in refrigerated foods is expected to reach 3% during this period.

What a cold storage warehouse is?

A cold storage warehouse is a specialized facility designed to maintain specific environmental conditions to preserve temperature-sensitive products. While they may look like typical warehouses from the outside, the internal structure is designed to meet this specific purpose.

Cold storage racks are an essential component of these warehouses, enabling the storage of food and medicines that require controlled temperatures to preserve their properties. These racks are usually made of stainless steel to withstand the harsh conditions of cold and freezing environments, and to maximize warehouse space and energy efficiency.

If you’re in the market for a cold storage warehouse, it’s important to prioritize features like temperature control, specialized storage racks, and energy efficiency.

Activities of a cold storage warehouse

Essentially, there are 2 main elements for making up basic types of cold storage warehouse:

- External warehouse

- Equipment used inside

Also, there is another third integrated option that combines both, where various racks are common to the design of most warehousing. In the cold storage warehouse, the rack designs are also one of the parts of the structure.

Irrespective of what type of construction the warehouses are made of, all cold storage facilities can play their part to keep their internal space at a controlled temperature constantly.

Broadly, cold storage warehousing falls into 2 categories dictated by the temperature that is needed:

- The refrigerated controlled temperature ranges from 0 °C to 10 °C.

- Fully frozen, with a temperature range between -30 °C to 0 °C.

There are different uses for each type of cold storage. A refrigerated storage warehouse is meant for food and aims to maintain the items at an optimum temperature that stops spoilage and also extends their life.

On the other hand, a cold storage warehouse must keep the product at a certain constant and stable temperature to diminish the damage risks.

Requirements and challenges

A few unique challenges need to be addressed to keep the products in cold storage and they are:

- The human factor – How will people work in sub-zero temperatures?

- The additional expense is to be incurred for energy to maintain the ambient temperature.

- How can the constant temperature be controlled, maintained, and monitored?

Working within a cold storage warehouse

There can be a few adverse effects of working within an enclosed environment at low temperatures. There can also be risks associated with human health as well as on the storage and equipment handling itself.

The Importance of Maintaining Consistent Temperatures in Cold Storage Warehouse

Maintaining consistent temperatures is essential to ensure the safety of food and other perishable goods stored in cold storage warehouses. Fluctuations in temperature can lead to spoilage and bacterial growth, which can result in foodborne illness and costly product losses. Therefore, it’s critical to regularly monitor and adjust the temperature settings in these facilities.

Meeting Cold Storage Warehouse Temperature Requirements

Cold storage warehouses must meet specific temperature requirements to ensure the safety and quality of the products stored inside. These temperature requirements vary depending on the type of product, with some items requiring temperatures as low as -40°C. Meeting these requirements often involves investing in specialized refrigeration systems, insulation, and other equipment designed to maintain the required temperature range.

The Advantages of Using Automated Temperature Monitoring in Cold Storage Warehouse

Automated temperature monitoring systems can provide numerous benefits for cold storage warehouse operators. These systems use sensors to continuously monitor temperature levels, sending alerts if any fluctuations occur outside the set range. This allows warehouse staff to quickly identify and address potential issues before they lead to product loss or safety concerns. Additionally, automated temperature monitoring can help companies meet regulatory requirements and provide documentation of temperature control efforts.

Pingback: Cold Storage Solutions with Warehouse Equipment