Patented solutions that temporarily rotate the load (up to 180°) to exchange pallets.

Top Industries Inc is the only company in the United States that offers advanced mobile, stationary, and fully automatic pallet inverters.

Patented solutions that temporarily rotate the load (up to 180°) to exchange pallets.

Top Industries Inc is the only company in the United States that offers advanced mobile, stationary, and fully automatic pallet inverters.

Solutions that exchange the pallet by applying lateral pressure or by pushing it.

Top Industries Inc is the only company in the United States offers advanced mobile, stationary, and fully automatic pallet exchangers.

Unique systems on the global market designed to exchange pallets for highly consistent and automated production flows.

Top Industries Inc is the only company in the United States that offers high-volume automatic pallet exchanger systems.

We've designed these solutions (available both in mobile and fixed versions) to separate product layers or create one tall load.

Solutions designed for speeding up the insertion and removal operations of freezer spacers (available both in the mobile and stationary versions).

Solutions designed to transfer products from slip sheets to pallets (or stack slip sheets into stackers).

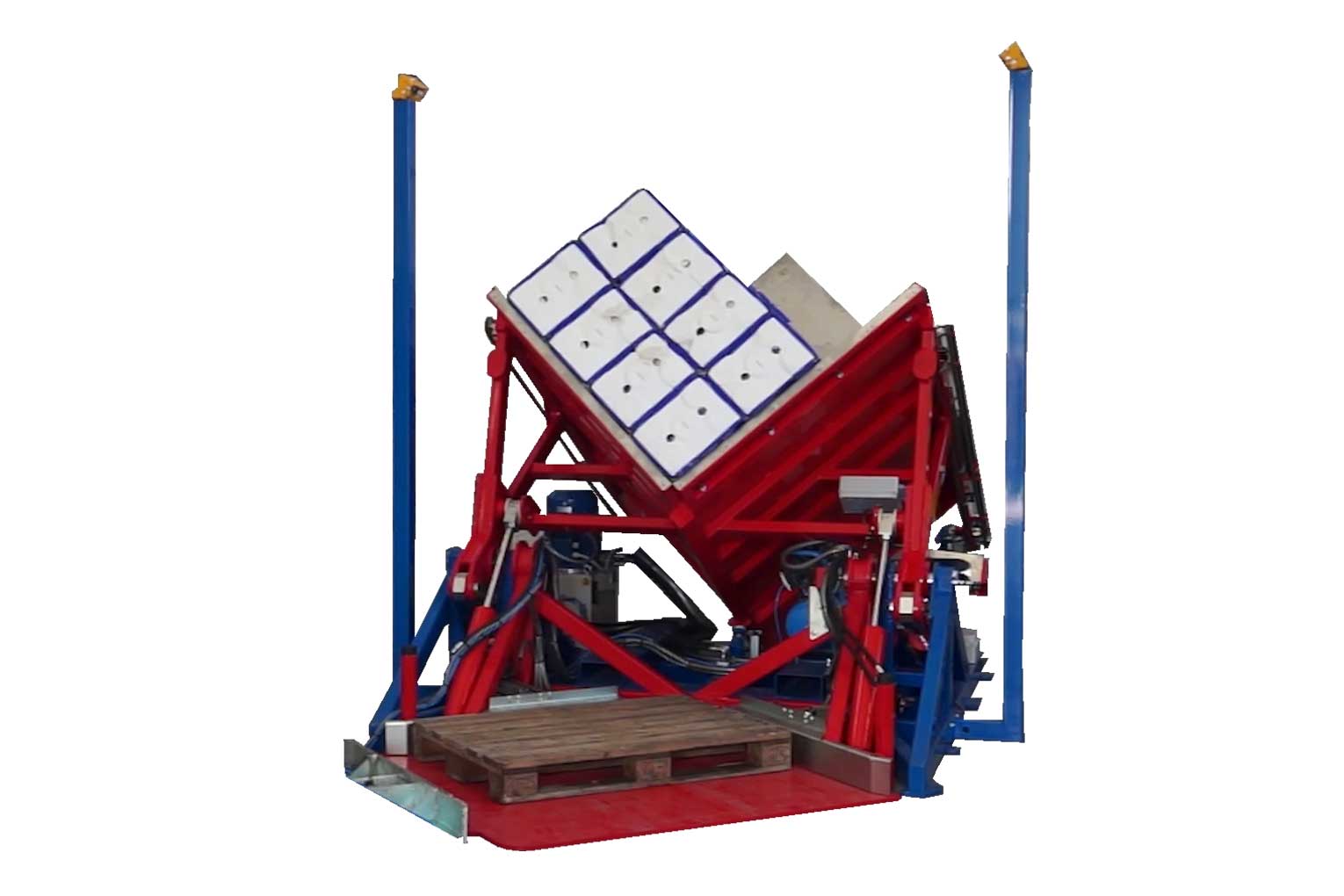

V-Shape 120° is one of our best seller pallet tipper all around the world thanks to the ability of handling most type of products in a very safe and fast way. Discover the original pallet tipper designed in the semi-automatic or fully automatic version.

Semi-Auto. pallet changing system;

Manage Up to 50 pallets per hour;

Ground-level loading and unloading

Products do not get damaged during the tipping

This is the Original Pallet Tipper designed by Toppy.

It diagonally tips pallet loads by 120° using a V-shaped movement structure. This method offers two-sided support for the load without any additional pressure. The changing task can be accomplished using a forklift or transpallet.

Here is an orderly list of how the Pallet Tipper works:

The operator places the load and initiates the cycle by pressing the controller panel button.

The entire load tilts by 120°, with the upper platform and two adjacent sides holding the products.

Once the load is secured in the boxed position, the operator presses the button to separate the lower platform, carrying only the pallet, from the load. The platform with the pallet moves down to the ground level.

A forklift or transpallet is used on the ground level for the pallet-changing task.

The operator presses a button to lift the lower platform to join the product load once the new pallet is placed.

With another press of a button, the entire load with the new pallet is tipped back by 120°. The load returns to the original position but with a new pallet.

The load is now ready to go. The manual tipper can repeat this pallet changing cycle up to 50 times per hour.

At TopIndustries Inc, we specialize in pallet handling solutions. If you want to enhance the productivity of your warehouse operations, reach out to us today!

At Top Industries, we offer a range of pallet tipper configurations, including automatic, semi-automatic, and fully automatic systems capable of handling up to 100 pallets per hour.

We custom engineered solutions for specific applications and suitable for low volume duty up to production duty for 24/7 operations across three shifts.

A tipper equipment is a material handling equipment that tilts its cargo bed to unload materials quickly.

A pallet tipper is a mechanical device that lifts, tilts, and empties pallets, crates, and other containers for easier and safer unloading or loading of products. It is a time-saving solution that improves productivity and reduces the risk of injuries caused by manual handling.

Pallet tippers play a crucial role in various industries, helping to smoothly and efficiently upend pallets to a 90-degree angle for easy repositioning and shipping. Our advanced mechanical pallet upenders are designed for seamless integration with your existing conveyor or material handling system. You can also load them with a crane, forklift, or pallet jack, providing the flexibility and convenience you need.

We offer a wide range of mechanical pallet tippers suitable for various applications. Whether you need to handle 10 pallets per hour or 60 pallets per hour, we have the right unit for you.

Pallet tippers are essential equipment for many industries, offering a quick and efficient way to handle pallets and materials. Here are some industries that use 90-degree upenders and mechanical tippers:

Car manufacturers and auto parts suppliers can use pallet tippers to efficiently handle and exchange from one pallet to another theirs heavy auto parts.

90-Degree pallet tippers can be used to handle large quantities of raw materials, such as powders and chemicals, in a safe and efficient manner. They can also be used for transporting finished products, such as medications, to different areas of the pharmaceutical facility or for distribution.

Our solutions are widely used in this industry to transport food and beverage products, including cans, bottles, bags, and boxes. They help to reduce the risk of spills and contamination and improve efficiency in food processing plants and beverage production facilities.

They can be used to handle large bags of pet food, making it easier to exchange pallets before shipping. They also help to reduce the risk of workplace injuries by minimizing manual handling.

Our pallet flippers can handle large quantities of meat, poultry, and seafood products, reducing the need for manual handling and improving safety in these environments. They are also used for handling and storing frozen products in cold storage facilities.

Pallet inverters can be used to manage large quantities of cosmetics, including bottles, jars, and tubes, helping to reduce the risk of damage or spills. They can also be used to handle packaging materials, such as boxes and cartons.

Pallet tippers are essential for handling and exchanging pallets of frozen products, including meat, seafood, and vegetables. They help to improve efficiency in cold storage facilities and reduce the risk of injuries due to manual handling.

Pallet upenders can handle large quantities of cheese and dairy products, including milk crates and cheese wheels. They help to improve efficiency in these industries and reduce the risk of workplace injuries.

Pallet tippers can be used to handle large quantities of chemicals and hazardous materials, improving safety and reducing the risk of spills or contamination. They can also be used to manage finished chemical products of different areas of the facility or for distribution.

At Top Industries, we offer a wide range of pallet tippers, from semi-automatic solutions to fully automatic pallet handling equiment. Contact us today to learn more about how we can help streamline your business operations and improve safety and efficiency in your workplace.

A pallet tipper is a valuable addition to any warehouse, offering two main benefits: increased production efficiency and improved safety. Heavy and bulky loads can be difficult to handle, disrupting production flow and creating safety hazards. With this type of machine, called also pallet turner machine, staff no longer have to manually exchange pallets, reducing the chance of accidents that can result in productivity loss, damaged products or pallets, or costly liability issues. Our equipments are designed with user-friendly motorized controls, making automation convenient and efficient.

Pallet exchangers, including 90-degree tippers and upenders, offer several advantages to streamline material handling and increase productivity. They can safely and quickly manipulate heavy and bulky loads without damaging products or pallets, which can interrupt workflow and incur costly liabilities.

Some of the key features of 90-degree tippers and upenders include:

With a pallet flipper, you can upend a pallet much faster than every other pallet exchanger or hand truck, saving you valuable time and effort.

Manual pallet exchange can be risky, but pallet flippers remove this risk by automating the process. With easy-to-use motorized controls, staff can operate the equipment from a safe distance, minimizing the risk of accidents and injuries.

Pallet upender come in varying capacities and can be customized to meet specific dimensions and weight requirements. This means you can choose the right equipment for your unique needs and optimize your workflow.

Pallet tippers are designed to handle even the toughest jobs and can withstand harsh conditions in a warehouse or manufacturing setting.

Some pallet turners are designed to perform secondary functions, such as stacking or unstacking loads, further enhancing their versatility.

At Top Industries Inc, we offer a wide range of pallet tippers and upenders that integrate seamlessly into your material handling process. Our material handling specialists can help you choose the right equipment for your needs and provide expert guidance on maximizing your productivity.

At Top Industries Inc, we understand that every business has unique needs when it comes to pallet handling. That’s why we offer customized pallet exchangers that can be tailored to meet your specific application requirements and technical considerations.

Our team of experts can work with you to modify our existing equipment, ensuring that it meets your exact specifications. Whether you require heavy-duty units for high-volume applications or lighter-duty equipment for occasional use, we have the expertise to design a solution that will work for you.

Our customized pallet tippers can be designed to handle varying capacities and sizes of loads, and we can even incorporate additional features to meet your specific needs. From specialized coatings to customized control systems, we can provide the solution that best meets your requirements.

At Top Industries Inc, our goal is to help you streamline your workflow and increase productivity with our high-quality pallet tippers.

If you are looking for a pallet tipper for sale, there are many options available in our production range. It’s essential to choose a reliable and high-quality equipment that meets your specific needs and requirements. A pallet tipper is an investment that can pay off in terms of increased productivity, reduced labor costs, and improved safety. When shopping for a pallet tipper for sale, consider factors such as the capacity, power source, control system, and safety features. Check out your ROI.

The capacity of a pallet flipper refers to the maximum weight it can handle, which can vary from a few hundred pounds to several tons. It is essential to choose a pallet tipper with the appropriate capacity for your applications to avoid overloading or underutilizing the equipment. The power source of a pallet exchanger can be electric, hydraulic, or pneumatic, depending on the type and size of the equipment. Electric pallet tippers are suitable for light-duty applications, while hydraulic or pneumatic models ideal for heavy-duty applications.

Safety is a top priority when it comes to material handling equipment, including pallet tippers. A pallet tipper that is not properly maintained or operated can cause serious injuries or damages to the products and equipment. Therefore, it is crucial to follow the safety guidelines and regulations when using a pallet tipper. Some of the safety features of a pallet tipper include emergency stop buttons, safety cages or gates, interlock systems, and overload protection.

To ensure the safe operation of a pallet tipper, here are some general safety guidelines to follow:

Pallet tipping refers to the process of emptying the contents of a pallet or container by tilting it to a certain angle, usually 90 degrees, and letting the products slide out. This is done using a pallet flipper, which can be manually operated, semi-automatic, or fully automated. Pallet tipping is an essential task in many industries, such as food processing, manufacturing, and warehousing, where bulk materials need to be handled efficiently and safely.

Top Industries is your trusted partner for material handling solutions, offering a range of advanced pallet changers designed to make your warehouse and distribution operations safer and more efficient.

Our knowledgeable sales representatives can help you find the perfect pallet tipper for your unique requirements, whether you need heavy-duty equipment for high-volume applications or cost-effective solutions for light-to-medium-duty tasks.

At Top Industries Inc, we pride ourselves on providing exceptional customer service and reliable products. Our experienced material handling specialists are dedicated to helping you optimize your workflow and increase productivity, while keeping your team members safe on the job.

Explore our inventory of pallet tippers today and contact us online or call us to learn more about how we can help you take your material handling to the next level.