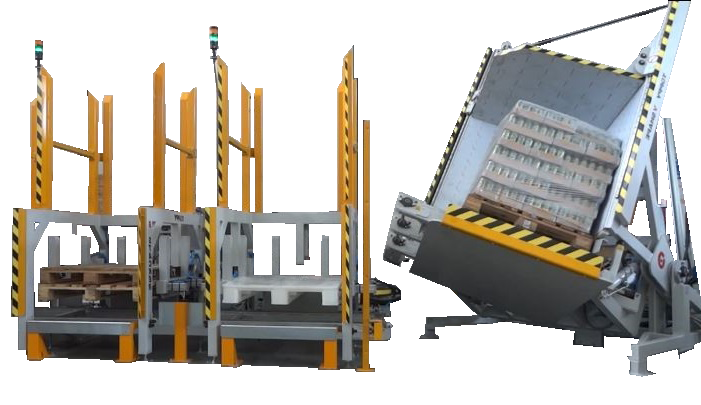

Patented solutions that temporarily rotate the load (up to 180°) to exchange pallets.

Top Industries Inc is the only company in the United States that offers advanced mobile, stationary, and fully automatic pallet inverters.

We supply fully automatic pallet exchanging systems that are customized to the specific workflow, type of products, pallets, warehouse area, and required level of automation.

Lift, exchange, and organize

pallets in tight spaces.

The fastest fully automatic pallet inverter on the market with patented technology.

L-SHAPE APSThe integration of the automatic pallet changer involves considering factors such as your specific conveyor height, the types of existing machinery, the hourly pallet change volume, the implementation area (inbound or outbound), product type, pallet specifications, and other pertinent project details.

Transferring products between pallets depends on the product’s configuration and handling requirements.

Some products are very heavy or very difficult to handle, requiring them to be tilted 120° (temporarily) in order to remove the old pallet and insert the new one. For other products, it is sufficient to press them laterally and lift them off the pallet to transfer them to the new one. There are other products that cannot be tilted or pressed laterally, so they are gently pushed from one pallet to another.

Contact our experts to find the most suitable technology for you!

A pallet transfer system is an automated solution designed to efficiently and seamlessly move goods between pallets.

By speaking to our experts who takes into account factors such as production flows, desired level of automation, and the types of products being handled, we meticulously analyze and identify solutions that align perfectly with the specific application.

Our goal is to ensure optimal performance and efficiency based on the unique requirements of each application.

Top Industries Inc offers the most advanced technologies not only in the USA but worldwide.

Our parent company and Italian manufacturer, Toppy, is the world-leading company for state-of-the-art pallet exchanging solutions. With a great deal of experience since being established in 1978 and supplying over 20,000 units in more than 147 countries!

Certainly! Consider that our systems are customized for each application.

They are capable of exchanging not only from one type of pallet to another but also exchanging from slip sheet to pallet (and vice versa) or from wooden board to pallet (or slip sheet) and vice versa.

The choice depends on your operations and current pallet handling equipment. Consider specific details, such as pallet stacking methods, container loading for customer shipments, and the configuration of your load and pallet.

Every aspect of your process should be taken into account:

Choosing a system tailored to your specific needs, accommodating various product configurations and pallet types will elevate your material handling process with precision and reliability.

By optimizing efficiency, reducing operational costs, and enhancing productivity, our solutions ensure a substanial ROI.

Utilizing specific data such as operator costs, and existing productivity costs, we develop a customized ROI projection for our customer’s unique case.

Our approach ensures a comprehensive understanding of the returns, empowering our customers to make informed decisions for sustainable business growth.

If you’re looking for an automatic pallet changer solution, get in touch with our experts by filling out this form.

We’ll assist in identifying the right solution for your needs. Alternatively, you can give us a call at 1-754-271-4310.