By using any plastic freezer spacers, it will be possible to obtain much higher ‘throughput’ by reducing chill down, thaw down or freeze down times.

How to remove and insert plastic freezer spacers?

The “L-Shape Splitter” is your ideal choice if you need to insert or remove plastic freezer spacers from the running load.

The operation is absolutely safer and faster thanks to this new revolutionary technology:

Why plastic freezer spacers are in demand?

With plastic freezer spacers it will be possible to obtain the desired refrigeration temperature within a much more economical time frame. In this way, it will enable a prompt turnaround for your next load.

There are a few frozen pallet storage who use such pallet freezer spacers so that they can facilitate free air circulation through each layer. But how to safely handle them?

Consequences of using freezer spacers

This will help the temperate air to quickly penetrate into the areas of the pallet that generally otherwise remain ‘insulated’ by the entire surrounding cartons whenever they will be stacked normally on a certain pallet.

The temperate air will be able to penetrate rapidly by interrupting each layer by using a plastic freezer spacer. This will help in improving refrigeration efficiencies tremendously and the product can be quickly loaded out at the required temperature.

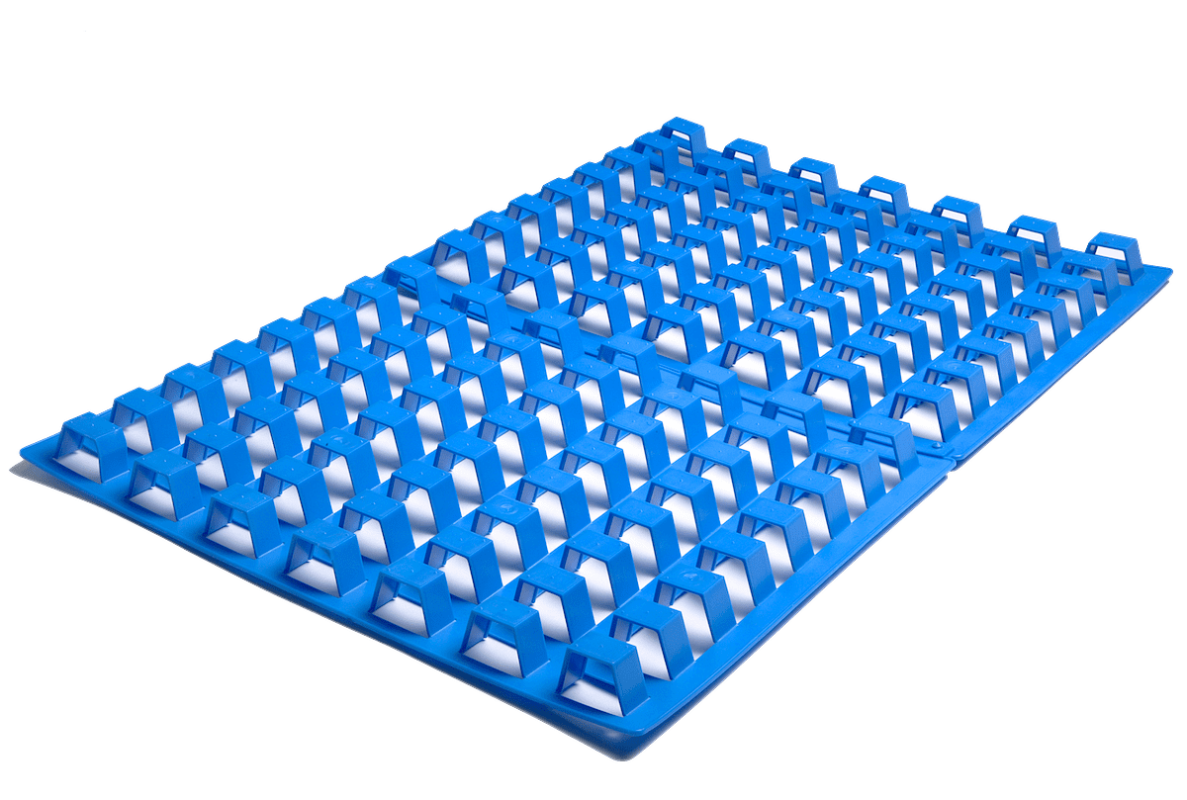

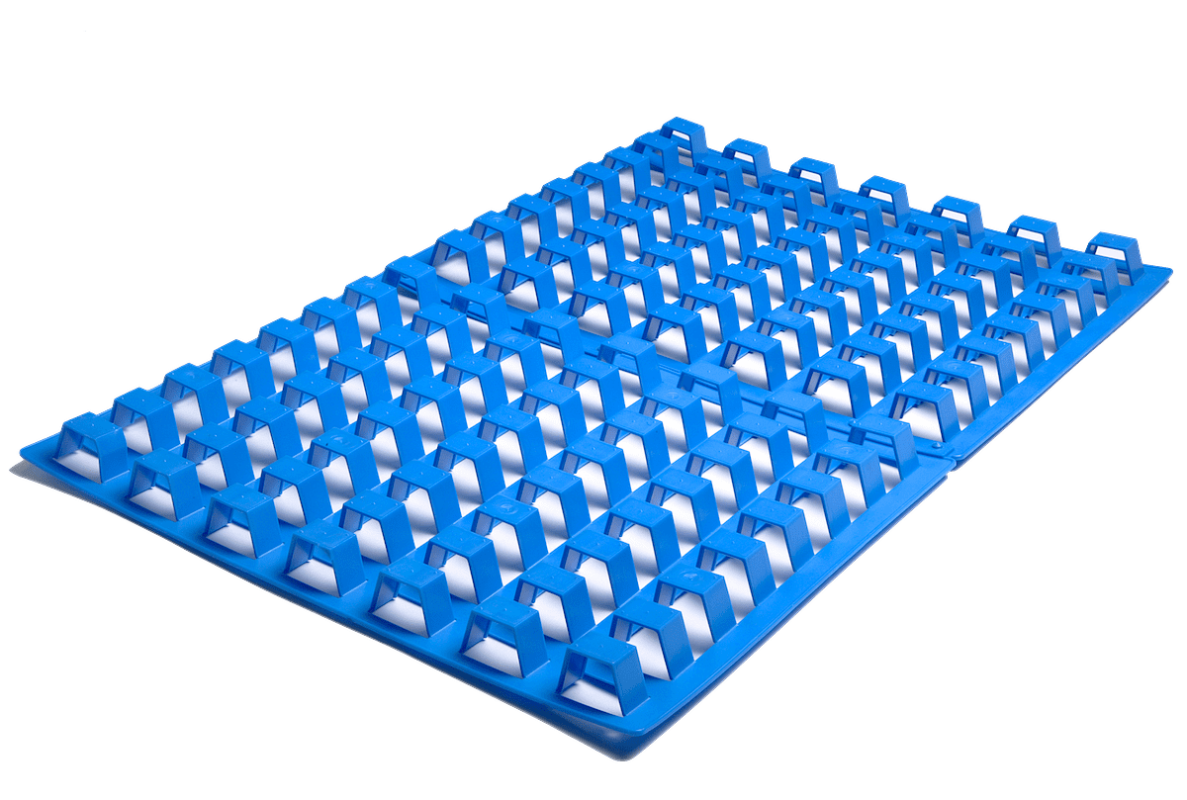

Design of plastic freezer spacers

These plastic freezer spacers can be designed specifically for any kind of pallets used in any cold storage or meat processing unit, so as to fit snugly inside within the boundary of any standard pallet sizing, which measures 45,2 inch x 45,2 inch.

The Mobile Alternative for handling freezer spacers

As we know, by using our portable pallet inverter, it is possible to turn the pallet, which may also be loaded with any stacked meat products, which will enable the freezer spacer removal from the stacked pallet very easily and conveniently.

Portable pallet inverters and plastic freezer spacers

If you are using pallet inverters in cold storage then retrieving any freezer spacers after the products carried by the box, which is already in frozen condition can be easily done within a few seconds.

There are many suppliers of pallet inverters available that can offer pallet inverters that can be of a wide range of specifications. They are available in both mobile and stationary versions. The combination of a pallet inverter and a freezer spacer can be a perfect match to work in this kind of application.

There are a few more advantages of using a pallet inverter in combination with freezer spacers:

- Using pallet inverters for retrieving freezer spacers can be much faster and safer compared to doing the same manually where you may have to re-pack pallets after completing the freezing process.

- No need for manual heavy lifting

- Reduced risks of product dropping or damaging

- Much faster compared to manual re-stacking.

- Safe and efficient handling

- You can reload all goods prior to entering any food or pharmaceutical zones

- You can easily replace any defective pallets or any damaged products of the line from the stack

- Exchange pallets with some other types e.g. wood, plastic, or metal

- Exchange pallets can easily be done with other sizes e.g. euro, half-euro, etc.

- In warehouses, you can pull defective pallets from your automated workflows

- Keep company-owned pallets and also ship rental pallets

- Freezer spacer pallets can easily be handled

A great approach to conserve electricity and lessen your carbon footprint is to use freezer spacers. They are a really sustainable option because they are made from just recyclable materials that can be recycled after they have served their purpose.

FAQ about freezer spacers removal system

The following are a few questions that are frequently asked about this product, which have been briefly answered.

-

Can we customize “L-Shape Splitter” for our special applications?

Yes, absolutely, we can always customize it according to your needs.

-

Which products will be suitable for this device?

This pallet upender can work with:

- Barrels

- Battery

- Big bags

- Big boxes

- Bottles

- Boxes

- Buckets

- Cans

- Flasks

- Large containers

- Packs

- Paper barrels

- Paper rolls

- Plywood

- Reels

- Trays

- Vials

-

What type of pallet can it work with?

Any standard or nonstandard pallets can be used for your operation whether it is made of wood, plastic, iron, aluminum, etc.

-

How the pallet change operation takes place?

By tipping your load at an angle of 90⁰ or 180⁰ based on your products.

-

How can we load/unload products from the pallet changer devices?

You can load/unload with the help of a forklift or pallet jack.

-

How can it operate with fragile products?

Even the most delicate goods are safely locked by the higher platform to safeguard the goods. In order to avoid the products from being crushed, the higher platform locks them with a gentle pressure controlled by certain limit switches and a shock absorber system.

Pingback: Look for a Right Equipment Solution for Your Frozen Foods and Cold Storage Business -

Pingback: the Various Advantages of Plastic Pallet Freezer Spacers?

Pingback: Tthe Importance of Freezer Spacers When Blast Freezing?

Pingback: Do You Know Why Spacers are So Important When Blast Freezing? - Immature Business

Pingback: Be Aware of the Pallet Freezer Spacer Systems - Business Junkee

Pingback: Best Practice Tips To Use Pallet Inverters In Cold Storage Facilities | Year Tearm

Pingback: Read to Know How to Manage Cold Storage Warehouse to Maximize Efficiency - AEV Corp

Pingback: Cold Food Storage Equipment (2023 Trends)

Pingback: 6 Steps to Follow for Better Warehouse Organisation - techbuzzireland.com

Pingback: Cold Food Storage Equipment (2024 Innovations)