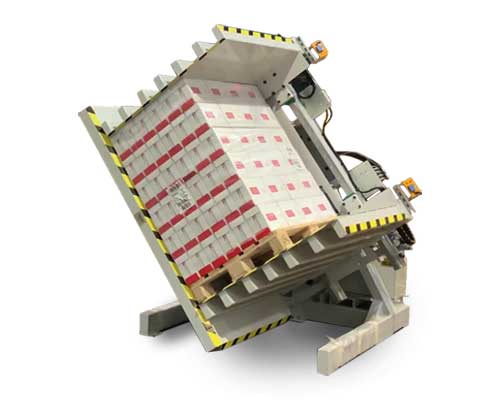

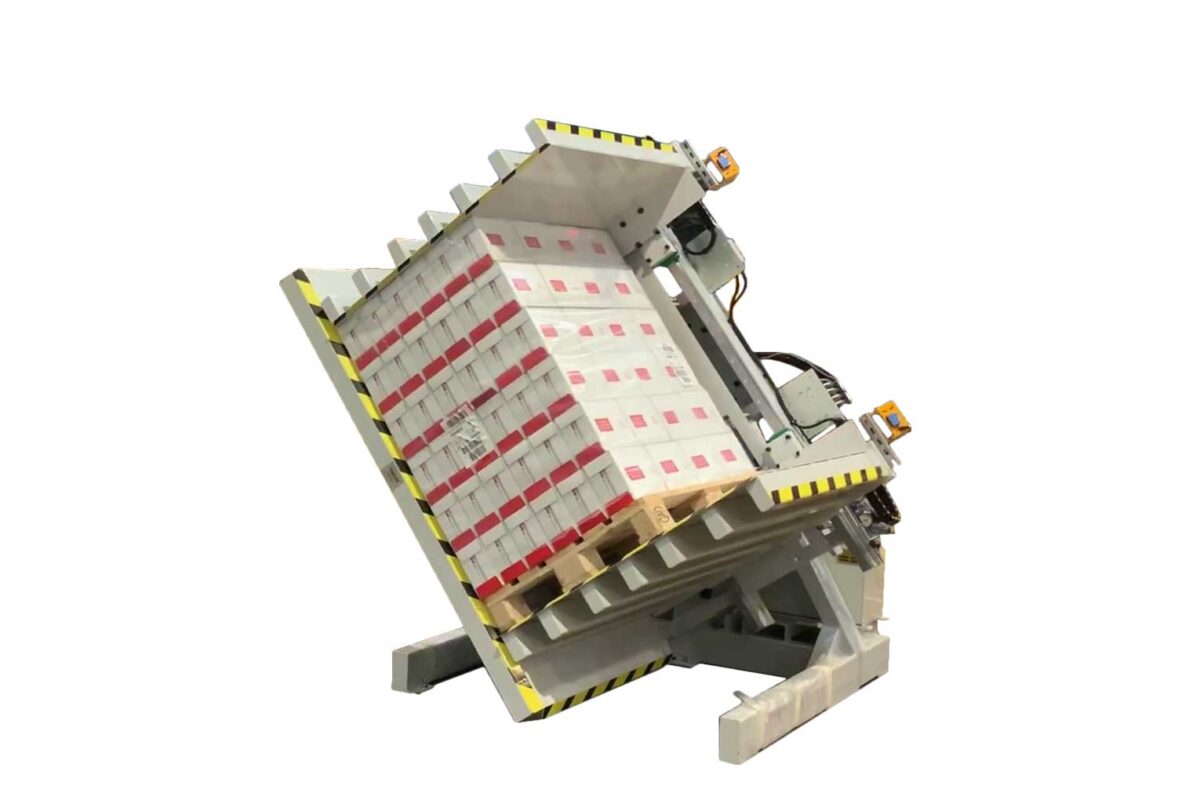

This below is the classic pallet flipper, originally designed by Toppy. Have a look at the New version of the pallet flipper machine launched in 2024.

Also available in the mobile version

Allows 35 pallet exchange per hour

Loading and unloading at ground level;

Can take loads up to 3300 lbs

Images for Pallet Flipper

Cycle Description of “Classic Ground Level”

This pallet flipper works by flipping the entire pallet load by 180°, sending the pallets to the top for easy exchange by the operator. The tipping of entire loads helps save time and labor in warehouses.

• To start, the pallet with the load is placed on the lower platform, which can be done manually using a forklift or automatically using conveyor belts.

• Two additional platforms are used to prevent the product from moving or spilling during flipping.

• The load is then upturned to 180°, allowing the operator to switch the pallets once they are on top of the load.

• Once the pallets are exchanged, the entire load is flipped back by 180°, bringing it back to its original position with a new pallet.

• The product is then released on the ground level for loading or stacking, where a forklift operator can take over.

This solution belongs to the broader category of pallet inverters, which are highly effective tools for handling and manipulating pallets in various industrial and commercial settings.

Discover the advanced version of pallet inverters

Have a look to Hands-Free, the advanced version of pallet inverters:

What is a Pallet Flipper?

A pallet flipper is a piece of material handling equipment used to turn or flip pallets over. This machine is designed to automatically rotate a pallet 180 degrees, making it possible to access and handle products on the opposite side of the pallet. Top Industries offers an advanced range of pallet inverters solutions to meet the needs of various industries, including manufacturing, warehousing, and distribution centers.

Versions of pallet flipping machines (Discover the complete range)

TopIndustries has been in the pallet-handling business for many years now. Our pallet flipping machines are also available in automatic and mobile versions. The mobile version is also easy to use, but you will need an operator and helper to oversee the operations. The automatic versions do not require that much effort as it does the pallets exchanging tasks automatically.

1. Mobile Pallet Inverter

The Maxi Pharma is designed to be moved around a facility to where it is needed most. These machines come equipped with wheels, making it easy to transport them from one location to another. This mobile pallet inverter is ideal for businesses that need to flip pallets in different locations around the warehouse or distribution center.

2. Stationary Pallet Inverter

The 120° V-Shape is designed to be installed in a fixed location within a facility. These machines are typically bolted to the floor for stability and are designed to handle high volumes of pallets. This stationary pallet inverter is ideal for businesses that need to flip a large number of pallets in a single location.

3. Inline Pallet Inverter

The L-Shape APS is designed to integrate seamlessly with conveyor systems. These machines are typically installed between two conveyors, allowing pallets to be flipped over as they move along the conveyor line. The inline pallet inverter is ideal for businesses that need to flip pallets in a very fast and automated way.

Learn more about our “Classic Ground Level”

This “Classic Ground Level” is capable of handling almost all types of loads, as it can take product weights up to 3300 lbs, having a length of 79 inches or less. The loading of this machine can be done on the ground level. The lower platform of this device is designed to go all the way to the ground, which allows for easy loading and unloading.

Benefits of Using a Pallet Flipper

Using a pallet flipper offers a range of benefits for businesses. One of the most significant advantages is the automation. This can increase productivity by reducing the need for manual handling and improving the speed of material flow. Consequently, the help to reduce the risk of injuries associated with manual handling, as well as minimize the risk of product damage.

1. Automating Your Material Handling Process

Automating your material handling process with pallet inverters can help to improve efficiency and productivity in your facility. Top Industries’ pallet flippers are designed to handle a high volume of pallets per hour, making them ideal for businesses with large-scale material handling needs. By automating your material handling process, you can free up your employees to focus on other important tasks while improving overall efficiency and reducing costs.

2. Customizable Pallet Flipper Solutions

At Top Industries, we understand that every business has unique material handling needs. That’s why we offer customizable pallet inverter solutions that can be tailored to meet your specific requirements. Our team of experts will work with you to design a pallet upender that fits seamlessly into your existing material handling process, improving efficiency and productivity in your facility.

A Versatile Pallet Inverter Machine (Patented)

When it comes to best pallet handling solutions, TopIndustries Inc has always been the Number 1 choice for thousands of companies. We have helped numerous warehouses and cold storage businesses maximize their productivity by using a minimal labor force. One of our top-selling products is this freezer spacer handling machine. Let us check out the features of this pallet flipping machine to understand if it is suitable for your needs.

Pallet Flipper Safety Features

When it comes to material handling equipment, safety should always be a top priority. Top Industries’ pallet turner machines are equipped with a range of safety features to ensure the safety of your employees and products. Our pallet exchangers feature safety guards, emergency stop buttons, and overload protection, among other safety features. These features help to minimize the risk of accidents and injuries in your facility, keeping your employees and products safe.

Pallet Flipper Maintenance

Like any piece of equipment, pallet inverters require regular maintenance to ensure optimal performance and longevity. Top Industries offers a range of maintenance services to keep your pallet tippers in top condition. Our team of experts can provide routine maintenance, repairs, and upgrades to your pallet exchanger to ensure that it continues to meet your material handling needs. With regular maintenance, you can extend the life of your pallet inverters and minimize downtime in your facility.

Choosing the Right Pallet Inverter for Your Business

When choosing a pallet exchanger for your business, it’s essential to consider several factors. One of the most critical factors is the size and weight of the product you need to handle. Different pallet flipper models have varying weight capacities, and it’s crucial to choose a model that can handle the weight of your load.

Another factor to consider is the type of material handling process in your facility. If your business relies on automated material handling processes, an inline pallet flipper may be the best option. These high-end machines can easily exchange about 100 pallets every hour without having to use laborers.

Finally, it’s essential to consider the space available in your facility. If you have limited space, a mobile pallet inverter may be the best option since it can be moved around as needed. However, if you have ample space, a stationary one may be a more permanent and efficient solution.

Benefits of Top Industries’ Pallet Flippers

Top Industries’ pallet flippers offer a range of benefits for businesses, including:

Improved productivity and efficiency: Our pallet rotators, also called as pallet upenders are designed to handle a high volume of pallets per hour, reducing the need for manual handling and improving material flow in your facility.

Enhanced safety features: Our pallet flippers are equipped with a range of safety features, including safety guards, emergency stop buttons, and overload protection, among others.

Customizable solutions: We offer customizable pallet flipper solutions that can be tailored to meet the unique material handling needs of your business.

Reliable performance: Our pallet inverters are built to last, with durable components and high-quality construction that ensures reliable performance.

Expert support: Our team of experts can provide maintenance, repairs, and upgrades to your pallet flipper, ensuring optimal performance and longevity..

Overall, choosing a pallet exchanger from Top Industries can help to improve efficiency, productivity, and safety in your facility. Contact us today to learn more about our pallet flipper solutions and how they can benefit your business