Pallet Inverters with Top Patented Technology for Pallet Exchange

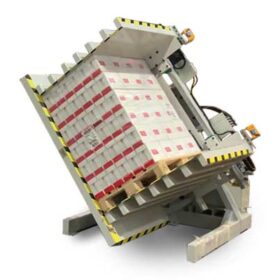

A pallet inverter is a powerful mechanized device engineered to rotate or flip entire palletized loads—typically by 180°—enabling swift pallet replacement, safe load transfer, and seamless material handling. There are several types of pallet inverters tailored to different operational needs: classic single‑clamp models for cost-efficient, semi‑automatic usage; portable mobile inverters for flexibility across production lines; and advanced inline fully automatic systems suited to high‑throughput warehouse automation.

These machines are invaluable across industries—from logistics and manufacturing to food, pharmaceuticals, and cold‑chain operations—where rapid pallet exchanges, reduced manual handling, and hygienic load management are essential. The benefits are significant: enhanced worker safety, minimized product damage, increased throughput, and optimized warehouse efficiency. Top Industries Inc. stands out as a technological and market-share leader in the U.S., offering over 36 patented pallet-changer models and drawing on its parent company Toppy’s pioneering legacy and global expertise, while continuously innovating to meet the evolving needs of modern industries.

Pallet Inverter – Mobile Turner 3300

The original portable pallet inverter designed for handling miscellaneous loads.

Pallet Inverter – Classic Inverter

The most economic pallet inverter in

our range of production.

Pallet Inverter – Hands-Free

The patented and advanced version of traditionals pallet inverters.

Pallet Inverter – Spider Inverter (Hybrid)

Exchange the pallets by using two modes: inverting the load or pressing it laterally.

Pallet Inverter – V-Shape

One of the most versatile machine, designed for handling miscellaneous loads.

Pallet Inverter – V-Shape Logy

Automatic pallet exchanger suitable

for handling miscellaneous loads.

Pallet Inverter – Game Changer

The ultimate evolution of pallet inverters, equipped with 2 pallet magazines.

Pallet Inveter – Fully Automatic L-Shape APS

The fastest fully automatic pallet inverter

with patented APS technology.

Why Our Pallet Inverters Lead the Market

At Top Industries Inc., pallet inverters are not just machines – they are the result of decades of engineering, innovation, and customer-driven development.

Companies across logistics, food, pharmaceuticals, and manufacturing choose us because we combine cutting-edge technology with proven reliability.

Types of Pallet Inverters

Fixed Pallet Inverters

A Fixed pallet inverter is a permanently installed unit, usually placed at the end (or entrance) of a production or packaging line. It’s designed for companies with high volumes of pallet exchanges and repetitive handling cycles. Their robust construction allows them to rotate heavy and tall loads safely. Fixed units are ideal in facilities that require minimal downtime and high efficiency.

Mobile Pallet Inverters

Mobile machines can be moved across different areas of the warehouse, making them suitable for operations where pallet exchange is not centralized. Mobile units are typically used by companies handling a wide variety of products in different locations, and they are especially valuable for facilities that need flexibility without dedicating a fixed space to the machine. Thanks to their mobility, they reduce downtime, allow operators to handle urgent pallet changes on the spot, and can easily adapt to seasonal peaks or shifts in production layout.

Inline Automatic Pallet Inverters

For large distribution centers and highly automated warehouses, inline pallet exchangers are the ultimate solution. Fully integrated into conveyor or robotic systems, they can handle thousands of loads per day with minimal human intervention. These systems reduce labor costs while maintaining high speed and consistency.

Use Cases of Pallet Inverters Across Industries

Food and Beverage

In the food and beverage sector, pallet inverters are used to replace wooden pallets with hygienic plastic ones before loads enter clean processing areas. They are also critical for switching freezer spacers, ensuring rapid cooling cycles without interrupting the supply chain.

Pharmaceutical and Healthcare

The pharmaceutical industry requires the highest standards of hygiene. Pallet flippers allow products to be moved from transport pallets to sterile pallets without manual re-stacking, minimizing contamination risks and ensuring compliance with regulatory standards.

Logistics and Distribution

Logistics companies benefit from pallet inverters by quickly replacing damaged pallets, consolidating mixed loads, or transferring goods onto standard pallets required by retailers. This results in faster turnaround times and improved supply chain efficiency.

Manufacturing

In manufacturing plants, pallet changers provide easier access to goods stacked at the bottom of the load. They allow partial unloading, quality checks, and repackaging without dismantling the entire stack, saving time and labor.

Key Benefits of our Machines

-

Enhanced Safety – By reducing manual handling, pallet inverters lower the risk of workplace injuries. Operators no longer need to lift heavy boxes or manually restack loads.

-

Time Efficiency – What traditionally takes 15–20 minutes of manual labor can be done in less than two minutes with an inverter.

-

Reduced Product Damage – Automated load rotation ensures goods are handled evenly, minimizing the risk of crushing or slipping.

-

Improved Hygiene – Switching from wooden to plastic pallets reduces contamination risks in sensitive industries like food and pharma.

-

Cost Savings – Lower labor costs, fewer damaged goods, and streamlined logistics directly impact the bottom line.

-

Versatility – From fragile goods to bulk packaging, pallet inverters can handle a wide range of products and pallet types.

Buying Criteria: How to Choose the Solution

Load Specifications

The first step is to evaluate load weight, height, and dimensions. Heavy-duty models are available for loads exceeding 3,000 lbs, while compact units are suited for lighter operations.

Frequency of Use

High-volume operations should consider fixed or inline models for continuous usage, while smaller facilities may benefit from mobile inverters that can be deployed as needed.

Industry Requirements

Sectors like pharmaceuticals or frozen goods demand stainless steel finishes and special hygienic designs. Food-grade pallet inverters are built with smooth surfaces and easy-to-clean components.

Space Availability

Evaluate the floor space in your warehouse. Fixed units require permanent installation, whereas mobile versions offer flexibility for operations with limited space.

Automation Level

For businesses embracing Industry 4.0, fully automated pallet inverters with integrated conveyor systems are the best choice. They connect seamlessly with WMS (Warehouse Management Systems) to support smart logistics.

Finding the right solution for you in 3 steps

We have a customer-focused approach that enables us to prioritize their needs with a dedicated offer creation process.

Start NowGet in touch with our experts

STEP 1

Answer the questionnaire

We provide you with a questionnaire asking for details about your operational needs, such as the type of product you handle. This helps us understand how we can assist you.

STEP 2

Our consultants will find the best solution for you

Through the information you provided, our consultants will analyze your information to build a customized offer based on your needs choosing among over 50 different pallet changer models.

STEP 3

Boost your production processes

With our tailored solutions, you can significantly boost your productivity by choosing a system that perfectly aligns with your specific needs and operational goals.

Suitable for every brand,

including yours

Our pallet rotators are engineered to adapt seamlessly to any industry and brand requirements. Whether you handle food, pharmaceuticals, beverages, or manufacturing goods, our machines are designed to manage different pallet standards and packaging formats with precision and care.

From global corporations like Nestlé, Pfizer, and Coca-Cola to mid-sized logistics companies, businesses worldwide trust our pallet inverter technology to streamline operations, ensure load safety, and reduce costs. Thanks to customizable features, advanced clamping systems, and durable construction, our solutions are not just universal—they are tailored to your brand’s needs.

With Top Industries Inc., you get more than a machine—you get a solution that works flawlessly with your processes, packaging, and pallets, ensuring efficiency and reliability in every load transfer.

Why Choose Top Industries Inc.

As the U.S. market leader in pallet exchangers, Top Industries Inc. combines advanced technology with unmatched market experience. With over 36 patented solutions and decades of expertise through its parent company Toppy, the brand delivers tailored pallet-handling systems for every industry. Whether you require a compact mobile inverter or a fully automated inline solution, Top Industries offers the most reliable and innovative equipment to optimize your supply chain.

Leading the USA

in pallet changing solutions

We stand out with our range of over +36 patented pallet changer models, offering tailored solutions to fit various products, workflows, and spaces, making us the leading choice for American companies.

Choose The USA LeaderGet in touch with our experts

+36 PATENTED SOLUTIONS

With decades of expertise and more than 36 patented technologies, we design and manufacture pallet changers and pallet inverters that are trusted by some of the biggest names in food, pharma, beverage, and logistics. From mobile units for maximum versatility to fully automated inline systems, our equipment is engineered to meet the highest standards of performance and compliance.

Our commitment to quality, innovation, and customer support has positioned us as the benchmark for pallet handling equipment in the USA, helping businesses reduce downtime, lower operational costs, and handle loads with unmatched reliability.

Pallet Inverter FAQ – Everything You Need to Know

What is a pallet inverter and how does it work?

A pallet inverter is a machine designed to rotate or tilt a fully loaded palletized stack of goods, usually by 90° or 180°. This allows you to replace broken pallets, switch from wooden to hygienic plastic pallets, or remove freezer spacers without manually handling the load. The process is safe, fast, and prevents product damage.

What is the difference between a pallet inverter, a pallet flipper, and a pallet rotator?

All three terms are often used interchangeably.

The three terms all refer to the same type of machine and are generally used as synonyms. “Pallet inverter” is the most common and technical term, widely recognized in the material handling industry. “Pallet flipper” is often used in the United States, especially in warehouse environments where the emphasis is on quickly exchanging pallets. “Pallet rotator” is simply another way of describing the same equipment and does not indicate a different category or function.

What capacity and speed (pallets/hour) do different models have?

Capacities typically range from 1,500 kg (3,300 lbs) up to 2,000 kg (4,400 lbs) per load.

Depending on the model:

-

Mobile units: 20–25 pallets/hour.

-

Stationary manual models: 30–40 pallets/hour.

-

Fully automatic inline systems: up to 100 pallets/hour or more.

How do I choose the right model for food, pharma, or cold-chain industries?

When selecting the right machine, it is important to consider the specific needs of your industry. In the food and pharmaceutical sectors, the best option is usually a stainless-steel or hygienic model, designed to comply with FDA and GMP standards and ensure maximum cleanliness. In cold storage environments, the ideal choice is a machine equipped with freezer spacer removal systems, which simplifies handling frozen goods. For high-volume 3PL warehouses, automated inline systems are the most efficient solution because they significantly reduce labor costs while maintaining high throughput.

Advanced Solutions for Pallet Handling

At Top Industries, we provide one of the most complete ranges of pallet handling solutions on the market, designed to optimize efficiency and guarantee safety in every stage of logistics. Whether you are managing food, pharmaceutical, or industrial products, our systems are engineered to adapt to your specific requirements.

Our line includes both mobile and stationary models, giving you the flexibility to operate inside a warehouse, on a production line, or in a dedicated pallet exchange area. The stationary pallet system is particularly appreciated in high-volume facilities where speed, stability, and reliability are critical. Depending on your load type, you can choose between a single clamp or dual clamp configuration, ensuring maximum security while reducing the risk of product damage.

We also offer machines manufactured in stainless steel, ideal for hygienic environments such as pharma and food industries. This material guarantees long-lasting durability and resistance against corrosion, making it the best option for companies that need to transfer goods safely across cleanrooms, cold storage, or industrial plants without interruptions.

Another strong advantage of our technology is adaptability: you can easily move from a wooden pallet to a plastic pallet, depending on logistics standards or customer requirements. Our systems make it easy to replace damaged pallets in the supply chain without stopping production. By automating this process, companies reduce labor costs and ensure compliance with international shipping and warehouse regulations.

Some competitors, such as Cherry Industrial, mainly supply entry-level machines suitable for standard use. Top Industries, instead, focuses on advanced engineering, offering solutions that cover everything from simple mobile units to fully automated pallet transfer lines capable of handling hundreds of loads per hour.

With Top Industries, you gain more than just equipment—you gain a reliable system designed to protect your products, reduce downtime, and maximize warehouse performance. From stationary pallet changers to automated transfer lines, we deliver tailored solutions that meet the highest standards of safety and productivity.

The Common Questions When Buying a Pallet Inverter

Certainly! We welcome customer visits at our showroom in South Florida to witness the machine operated. If the machine is a specialized solution beyond our standard production, we can organize a virtual demo with our colleagues in Italy.

Yes of course, we have many options! Some of our machines are specifically designed to handle the most fragile products, even at high speeds. Rest assured, we’ve got the best solution for your needs.

To find the best solution for your needs, we start by analyzing your products, the pallets you work with, and most importantly how many pallet changes you make per hour. With this information, we can quickly recommend the most effective solution for your specific case.

To use a pallet inverter machine effectively, follow these steps:

1. Load the Pallet: Position the loaded pallet on the machine’s platform.

2. Secure the Load: The machine clamps the load securely, ensuring stability during the inversion process.

3. Invert the Pallet: The machine rotates or tilts the load, allowing for easy removal and replacement of the pallet.

4. Replace the Pallet: Swap out the old pallet with a new one.

5. Return to Position: The machine returns the load to its original orientation.

Consider using a pallet inverter with the patented APS (Automatic Pallet Stacking) technology like the Hands-Free. This advanced system automates the entire process, ensuring seamless, safe, and efficient pallet exchanges.

Top Industries Inc offers the most advanced technologies not only in the USA but worldwide.

Our parent company and Italian manufacturer, Toppy, is the world-leading company for pallet exchanging solutions. With a great deal of experience since being established in 1978 and supplying over 20,000 units in more than 147 countries!

Most companies recover their investment in a pallet inverter within twelve to twenty-four months. The return comes from multiple factors combined: lower labor costs due to automation, improved safety for operators, reduced expenses for pallet replacement, and an overall increase in productivity across the supply chain.

It’s one of our strengths. Our after-sales team is available 24/7.

For both mobile and fixed machines, we always offer an emergency spare parts kit. If additional parts are needed, we have a fully stocked inventory in Davie, Miami, and can ship what’s necessary within a few business days. In the case of a machine needing a repair, we have a team of talented technicians ready to be deployed. For automated solutions, we always schedule routine maintenance after the purchase to ensure everything is running smoothly.