These days, the warehouse pallet automation in many companies including the food and pharmaceutical industries are constantly evolving their automated pallet warehouse.

Discover how to reduce cost and increase internal margings in warehouse pallet automation and how to save time by speeding up the processes. You will discover also how to safeguard the workers in the automated pallet warehouse.

As a result, the continuous enhancement in warehouse pallet automation technology has developed in every phase of internal management, right from the entry to exit of materials and products to internal production.

The logistics evolution in the automated pallet warehouse

One of the big reasons why this new logistics evolution is happening is because of the constant demand for performance improvement, the efficiency of the automated pallet warehouse, speeding up various operations, and much more.

This also originates from the various methods employed to measure performance which is very much specific and may take into account several factors. All these will certainly lead to making an impact on the supply of a certain warehouse pallet automation and offer gain in terms of financial advantages.

The Automation with pallet changing system

The new solutions that have been developed are the results of different needs of the market.

One of the problems that are often faced by most industries is to evolve a suitable method to obtain fewer materials wastage and also time, which is in the context of increasing the speed.

The trend with pallet transfer systems that has become more apparent recently is the rise in demand for automation. This transformation is unprecedented for all markets because it fundamentally transforms every internal procedure.

With the introduction of warehouse pallet automation manual labor is replaced, which will in the long run favor a net reduction in operator costs. The recent pandemic situation has also somehow contributed to this new transition.

When various unnecessary activities were suspended, those companies that had already owned automated pallet warehouses were not very much affected by any slowdown. All such combination of events has finally, therefore, led to a further enhancement in the automation of storage processes.

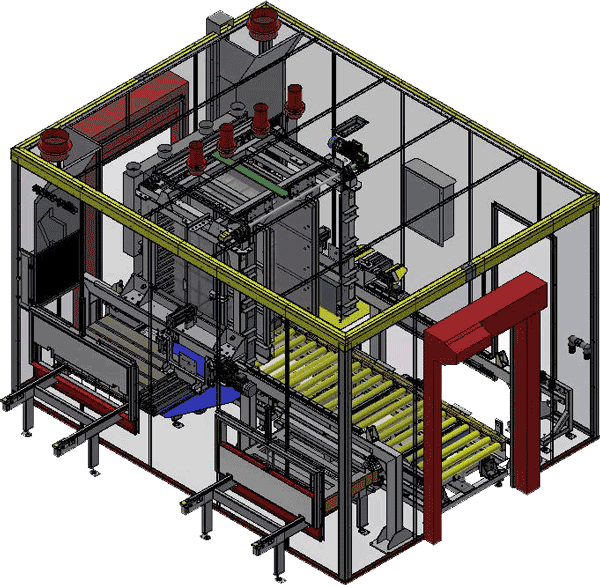

Keeping in view of such a scenario, engineers of those companies manufacturing material handling systems have come up with a production line solution where a new pallet changing system has been introduced to satisfy this kind of need as well.

How fully pallet changing systems functions

Similar to stationary and mobile pallet exchangers that are available with the product range of various material handling system manufacturers, the completely automatic pallet inverter systems can also manage any kind of product having different replacement methods:

- Load rotation

- Load tipping

- Lateral pushing or clamping

One of the factors that lead to such kind of systems is the total absence of staff who are dedicated to carrying out the whole operation. The result of such implementation, consequently, has come up with automatic product management on pallets in automated pallet warehouse.

In the new decade, these fully automatic pallet changers can meet the needs of many companies. This can help in increasing productivity, reducing costs, and zero waste is also ensured.

These pallet handling equipment have been especially dedicated to bigger companies where there is a consistent flow of products for managing.

With this system, it is possible to change more than 100 pallets/hour. When any such need arises, the speed improvement and also money-saving tactics justify the choice of a certain automatic pallet changer.

In the USA, where there is a presence of so many large multinational companies, there are also, many consistent flows of both incoming and outgoing products where these systems can work very well.

The simplest way of changing pallets

A pallet changer that uses the clamping method can be used either as a stand-alone element or can be integrated into any material flow system. The exchanger can be loaded and offloaded by an electric pallet truck or by using a manual method.

Side walls will clamp the load and the pallet will then be lowered by using the pallet truck. Now with this method, the pallets can easily be changed fast. This is integrated into the material flow system where the pallet changing can be performed using a lift conveyor. The clamping process will neither invert nor tilt the load.

This kind of clamping method is suitable particularly for goods that remain stable under pressure and also stacked squared up without any gaps. This type of pallet changer can also reduce price and is also an easy application.

The clamping walls can grip the stacked goods from 2 sides and fix them. Then the pallet will be lowered and removed. Hence, it can be replaced by any other load carrier easily.

This procedure will be suitable for the pallet exchange of any insensitive goods like cardboard boxes, crates, or boxes for beverages. They can be moved in with the help of an electric or pallet truck. The pallet handling could alternatively be made fully automatically by via a conveyor line.

The robust and modern pallet changers that are available with various material flow systems are able to make up to 50 changes/hour. These changes can also be effortlessly incorporated into automated pallet warehouse.

By using this clamping process, one can exchange any type of pallet whether it is a Euro pallet, any plastic pallets that are needed by the hygiene sector, or space-saving type Düsseldorf pallets.

Inexpensive solution for automated pallet warehouse

If you are looking for any inexpensive pallet changer for your robust items then go for the clamping method. Here, your items are fixed firmly on 2 sides when changing the pallet. Then the pallet will be lowered by any pallet truck/lifting roller conveyor and exchanged.

These pallet changers by using the clamping process are used as stand-alone elements, free-standing and are also integrated into your material flow systems.

Here you can handle up to 50 pallet changes in an hour. Such inexpensive clamp pallet changers will be especially appropriate for low pallet quality.

These palletizers are perfect for packing goods that are pressure-stable and can be packed within crates or boxes without gaps. It makes no difference how heavily filled the pallet is. The side arms’ pressure is all that the products must withstand.