For many companies, custom material handling solutions can be crucial as they need to store and handle bulk material. Most equipments are related to controlling, moving, protecting or storing material through different processes in warehouses.

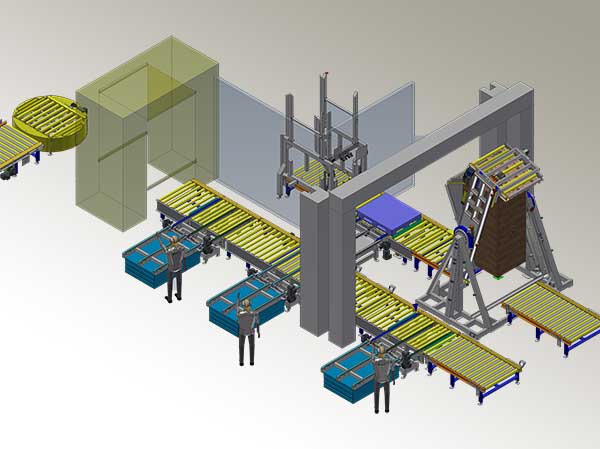

For building unit loads or stable pallet for adapting to changing packaging styles most manufacturers rely on certain flexible, end-of line palletizing systems. We offer custom materials handling solutions for pallet exchanging.

When it is needed to handle raw materials in any manufacturing facilities like with empty bottles or jars, often manufacturers prefer to integrate de-palletizers for quickly unloading bulk materials in secondary processes that can support production line efficiencies.

Such environment also utilize certain advanced robotic tooling for enabling the flexibility required for handling a variety of separator boards and sheets, as per unique requirements of each manufacturer.

With the recent corona virus effect that still shadows our everyday life, a plenty of uncertainty hangs over the industry of custom materials handling as we are moving into 2022.

Nevertheless, the industries will have to move on despite the uncertainty, which means that the investments will need to continue on supply-chain in order to adapt to the changing market conditions.

That should make the coming year another busy and dynamic year for the operators of warehouse and their automation partners. Here are 4 macro trends that we can expect in the coming year.

Item picking is now moving upstream

Smaller order sizes have been on the rise recently, and in 2022 that trend will continue as centralized pallet and case warehouses start incorporating individual item selection into their workflows.

Retailers are forced to reduce the size of their Stock Keeping Unit (SKU) size, in order to cut down on the costs of operations. It became more difficult for business that need to store slow-moving products in the market, as the storage recourses will need to be extended for a longer duration. They will have to think of some other alternatives to go hand in hand with their products as custom materials handling solutions.

As a result, numerous warehouses will undergo transformations as they implement new procedures and technological advancements to facilitate effective item selection. In warehouses that traditionally supported solely pallet and case handling, goods-to-person technologies like cube-based automated storage and retrieval systems and mobile autonomous robots will find a place.

Additionally, this tendency will hasten the deployment of robotic item-picking systems. This technology has the potential to totally automate the picking process, assisting operators in adjusting to personnel shortages and cost pressures, and offers significant advantages for material handling operations.

Grocery retailers prefer to crystallize their MFC strategies with custom materials handling

The corona virus pandemic’s effects on the uptake of e-grocery have been extensively studied.

Although it has dropped down since the frenzied early days of the epidemic, demand for e-grocery services is still significantly more than what grocery stores anticipated it to be just two years ago.

The same trend that we saw in other e-commerce marketplaces is currently being seen in e-grocery as well: rising consumer expectations for quick order fulfillment.

Grocery transportation and fulfillment is usually a time-sensitive process, as the products have to reach the market at the earliest, due to their short shelf-life. This market does not get as much flexibility for taking the time on transportation and fulfillment, like other e-commerce products. Customers are usually impatient about getting their daily grocery when compared to other products, and they prefer freshness of the things they purchase.

This has rendered in-store manual fulfillment is impractical in many places for large volume shops. Picking in-store wastes money causes congestion and irritates in-store customers.

In 2022, those firms will develop trust in the MFC concepts that have been implemented thanks to the experience of early adopters. They now know the crucial details that prevented widespread acceptance.

Supply chain connectivity has started delivering global inventory visibility

The difficulty to obtain a comprehensive view of inventory across worldwide distribution and retail locations is one of the gaps that many supply chains have.

This is a concern since it makes it more difficult to respond to both specific consumer needs and broader market adjustments in today’s fast-paced and constantly changing distribution ecosystem.

This data is easily accessible at each location thanks to the digitalization that has already taken place in warehouses and retail establishments. However, it might be difficult for individual firms to create interfaces across the many software platforms in a specific distribution network.

Software solutions with the ability to link several systems throughout a worldwide organization and provide a consolidated picture of inventory and its condition have a substantial market opportunity.

We will surely not be able to find the perfect solutions to the issues in 2022, but the attempts and focus to improve the supply-chain systems will have to continue with full vigour. The main aim is not just to meet the market demands, but also to offer costum material handling equipment for each customer characteristics.

Custom materials handling equipment allows better flexibility

Warehousing and distribution units will need to adapt to the evolving market trends in order to sustain the tough market conditions. Automation of operations will leads to better performance and increased productivity. It also helps them save more in time and resources needed for operations..

Custom material handling automation that is adaptable and scalable first became popular in e-commerce fulfillment because those systems made it possible for e-tailers to respond to changing demand and rapid expansion in ways that traditional automation simply couldn’t. These systems are currently being expanded to accommodate new applications.

These systems enable warehouse operators to increase throughput and inventory separately in a variety of applications, from item picking to pallet handling.

They are capable to drive higher performance with similar inventory or expanding inventory without needing higher performance.

The industry of custom material handling has seen unparalleled change over the last few years. Responding to all those changes was frequently an all-consuming task in real time that detained longer-term preparation.

Nowadays, as we are going to enter 2023, many companies will find they simply cannot stretch their existing resources and systems any further. Certain new distribution strategies and technologies will be needed to meet the new challenges and to acclimatize the unanticipated changes of the future.

Pingback: Top Ways You Can Speed Up Production - Apollo Technical LLC