How to choose the safest pallet changer equipment?

It is critically important to identify safest pallet changer equipment that significantly improves your productivity and is also capable of solving serious ergonomic problems, while at the same time solving safety problems.

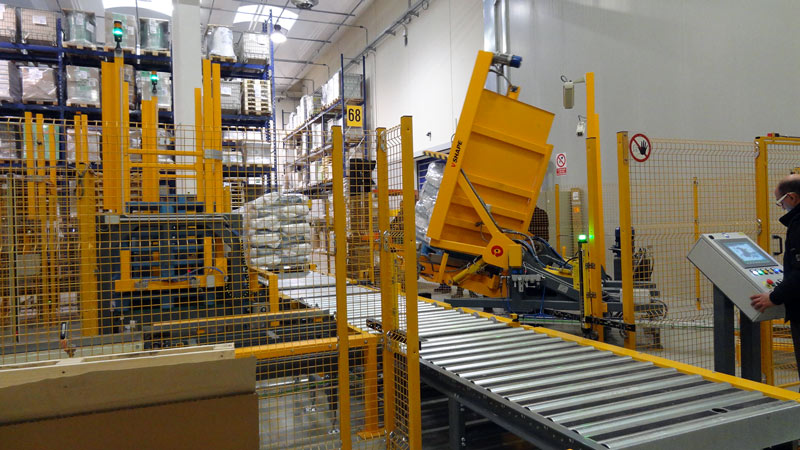

Before acquiring new pallet changer for your company, we recommend that you fully understand what is included in the offer and what standard options are provided. In evaluating the pallet changing solutions, TopIndustries makes itself available in providing scheduled maintenance, managing incoming products by providing technologically advanced equipment, and ensuring a very high level of safety in order to not damage the products and significantly reduce accidents at work.

Where to start for identifing the safest pallet changer equipment?

We fully understand the difficulty that there may be in identifying the pallet handling equipment for handling materials that is best suited to the safety needs of products and workers. Generally, many companies take the position that the safe operation of the machine is the sole responsibility of the purchaser and not the manufacturer of the machine. With TopIndustries, the question is different: being confident in the advanced technologies we have available, as they ensure a very high level of security, we encourage our buyers by taking responsibility for the operation. Our machines have the ability to work autonomously 24 hours a day without stopping for an indefinite period. The online search results show that there are a couple of companies that only provide paid support services and security updates to verify operation. Pay attention to the mediocre approach of these companies, acquiring a low-quality machinery for the reduced cost will certainly involve unexpected, unwanted and unnecessary costs.

Identify the company you can trust!

TopIndustries has been operating in the logistics and load handling sector for over 40 years, optimizing production processes by saving time and money but above all by significantly increasing the safety of products and workers. Our experts are at your complete disposal in identifying your safety risk and investigating risk-free pallet inverter projects, with protections and safety devices. The types of certification that are acquired and the regulations that must be respected will be explained in order not to incur risks at work or even unpleasant sanctions.

More about this source textSource text required for additional translation information

Send feedback

Side panels

Safety for pallet changer equipments

All Top Industries equipment are equipped with safety systems to prevent accidents at work, with particular attention to GMP standards to ensure the appropriate quality standards.

In the specific case of mobile pallet changers, they are supplied with safety braking systems for handling the trolley. In addition, an emergency button is installed. When activated, the operation is immediately stopped. We also provide optional side nets, for extraordinary cases, if the product was to ever fall during the overturning or rotation process.

The MEKKANO gate combines with the components of the EASY BARRIER perimeter protection to overcome the limits of welded framing.

Using the pre-painted elements and original connecting systems with screw fastening, it is possible to assemble gates of different widths in a rapid and clean way, making them ready to be installed. With the same elements, the MEKKANO gate can be prepared in the right or left configuration, with outward or inward opening.

All the configurations of the gate can be obtained either for the version with the upper support or without it. The high strength of the connecting elements makes the structure as rigid as a classic welded frame.

Technical support

Technical support is free for customers with TopIndustries. Detailed information is provided on the installation and operation of the pallet exchanger and your staff will be assisted with the aim of activating the system as quickly as possible.

– Free technical assistance and real-time response

– If the machine we supplied stops working, it becomes our priority! Your call is valued and more team members will be used to help you solve the problem and get back to carrying out the pallet change operation as quickly as possible.

– TopIndustries makes available the team of experts, mechanical engineers, electrical engineers, and safety managers

– Organized support for the entire life of the machine

– Information archive on your machine, problems encountered, and solutions implemented

– Technical advice and maintenance planning for all TopIndustries customers.

Our service team is always available to update the best methods to better support customers and solve problems that occur with pallet changing equipment. Do you need technical support? Contact our support team directly to request immediate assistance at 1-754-271-4310 or send us an email at info@topindustriesiinc.com

Scheduled maintenance

The real secret to minimizing mechanical failures and decreasing numerous service calls is surely the scheduled maintenance of the pallet inverter / pallet turner equipment. It is of fundamental importance to have an optimal and long-lasting operation of the device, to organize and prepare the pallet replacement operations with scheduled maintenance to ensure that the process is not interrupted by unexpected failures.

To meet the needs of each customer and to prevent any type of damage to the pallet changing equipment:

– Carrying out scheduled maintenance on the pallet exchanger solution allows you to minimize the loss of productivity, reduce mechanical problems, excessive wear, and unexpected operating stops;

– Scheduled maintenance extends the life of the pallet changer solution

– Organizing maintenance in advance and systematically pays off economically

– With scheduled maintenance you prevent hydraulic and electrical problems. For example, by inspecting the correct functioning of the hydraulic fluid and filters;

– A correctly maintained machine is certainly safer in the operations to be performed and will make products and operators safe.

TopIndustries prepares special programs for specific pallet changing equipment, with the aim of inspecting the general conditions of the system, identifying the replacement of parts, and finally recommending a subsequent level of assistance and maintenance.

There are different levels of maintenance depending on the need and frequency of use of the machine. Generally it is important to grease the critical points, check that all buttons and indicators are working correctly, check the fluid levels, and the correct functioning of the filters. In the long run, our expert technicians will take care of replacing the oil filter and checking that all bolts are tightened correctly. After 1 year from the acquisition of the pallet tipper device, generally, our expert technicians take care of having a complete overview of the machine, checking all the pipes and any signs of wear and abrasions, which will certainly involve a replacement of what has been damaged .

Do not hesitate to contact us if you need assistance or scheduled maintenance, our experts are always available to help you in everything you need!