Pallet Inverter Solutions | Advanced State of the Art Engineering

We’ll recommend the most suitable pallet inverter solution based on your load, production flows, and the required level of automation. Our experts will advise on a product range with more than 50 different models, designed for every application.

Top Global Companies Choose Our Pallet Inverters Solutions

The New Evolution Pallet Inverter

At TopIndustries, we are proud to offer new patented pallet inverter & pallet exchangers designed to meet diverse challenges and requirements. This “ultimate evolution” is one of our latest technology, “The Game Changer” equipped with two pallet dispensers.

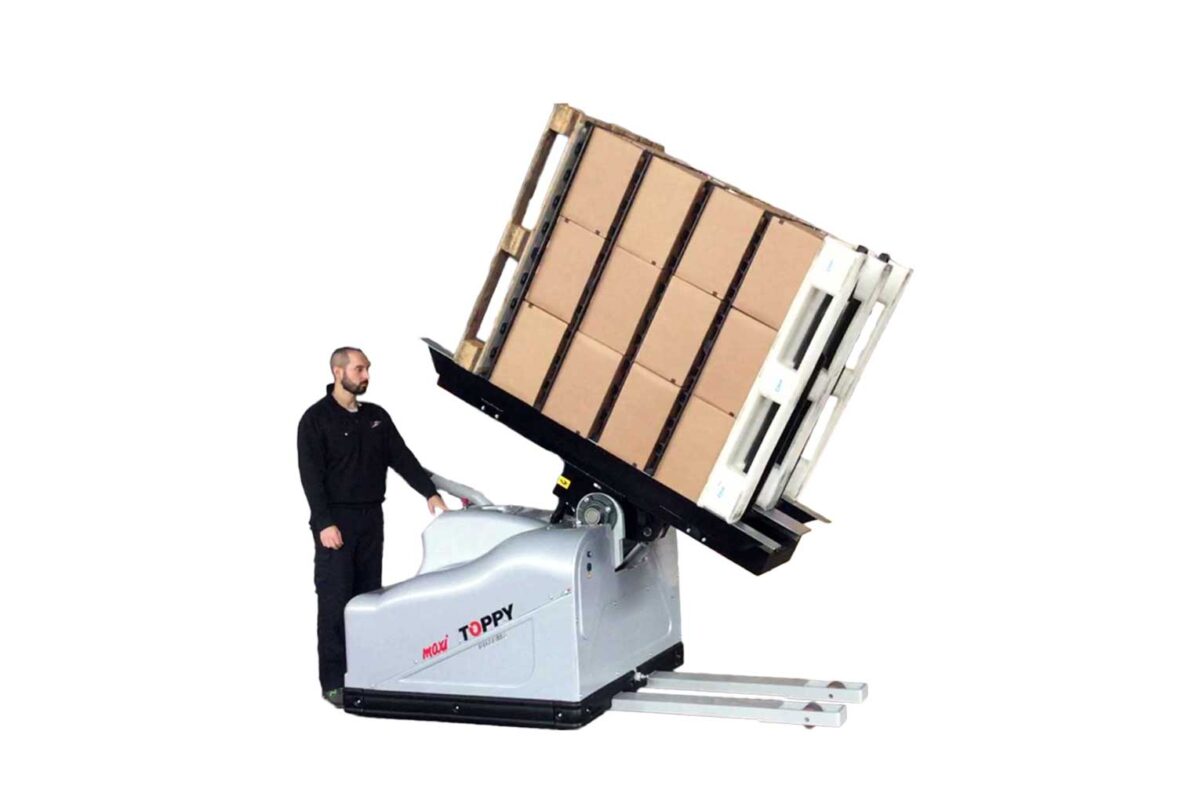

The Original Portable Pallet Inverter

Our “Turner 3300” is perfect if you need a versatile solution as it can be moved like a forklift or pallet truck. This is one of the most versatile pallet inverter for sale on the market.

Introduction to Topindustries Inc. Pallet Inverters

Topindustries Inc is a leading company in the United States in the field of pallet exchangers. Our solutions are designed to make the task of pallet exchanging easier, more efficient, and safer. With a wide range of models, we are able to meet the needs of any business.

Pioneering Progress: The Innovative Production Line

Our latest and revolutionary solutions are best suited for various industrial applications, including pharmaceuticals, food and beverage, ceramics, and more.

People Also Ask

A pallet inverter is a material handling equipment used to rotate or invert pallets, typically to transfer goods from one pallet to another or to access items on the bottom of a pallet easily. It is a valuable tool in logistics and warehousing for efficient pallet management and product handling.

Using pallet inverters offers benefits such as product protection, efficient handling, space optimization, cost savings, versatility, and enhanced safety and hygiene.

The purpose of a pallet inverter is to rotate or invert pallets, facilitating tasks like transferring goods between pallets, accessing items on the bottom of a pallet, and optimizing warehouse storage.

To use a pallet inverter, place the loaded pallet on the machine, secure it, and activate the inverting process, which rotates the pallet 180 degrees, allowing for efficient product transfer or access.

A pallet changer is a machine that automates the process of replacing a loaded pallet with an empty one, optimizing material handling and reducing manual labor in warehouses and manufacturing facilities.

Pallet Inverter & Pallet Exchanger Manufacturer

From conceptualization to production, our unwavering commitment at Top Industries Inc lies in the development, construction, and maintenance of high-quality solutions tailored to help you achieve your objectives. Whether you’re aiming for reduced downtime, enhanced quality, increased efficiency, improved productivity, heightened safety, or lowered costs, we stand ready to assist with professional service and reliable expertise.

The Most Advanced Pallet Exchanger Solutions

Top Industries Inc offers cutting-edge equipment, including fully automatic pallet inverters with a 180-degree rotation capability, ensuring swift, easy, and secure pallet transfers while minimizing product damage. Our machines are designed to overcome various challenges, with the broadest range of pallet flippers available in the market.

Customized Pallet Inverters different Across Industries

Top Industries caters to a wide array of industries, delivering customized material handling solutions to our clients. Our primary sectors of operation span food and beverage, pharmaceuticals, agriculture, automotive, retail, logistics, chemical, distribution, meat, poultry & seafood, cold storage, cheese & dairy, cosmetics, bakery, and more.

Optimize Efficiency with Top Industries’ Pallet Inverters

Enterprises aiming to optimize their operational workflows and elevate overall efficiency routinely gravitate towards the versatility and effectiveness of pallet inverters. At Top Industries, we understand the paramount importance of seamless material handling within the business framework. With a robust history of specialized expertise and a well-earned reputation for consistently delivering superior quality and exceptional service, Top Industries has emerged as the undisputed leader and preferred partner for businesses spanning a myriad of industries.

The Advanced & Patented Pallet Inverter model

This model is capable of transferring goods with a maximum weight of 3300 pounds and can be customized to any opening range that fits your product. The “Hands-Free“ improves upon the pallet inverters of the old. This patented pallet inverter requires no manual work from operators. We guarantee you won’t find this technology anywhere!

An Alternative to fixed solutions

“Turner 3300” is the ideal choise for manufacturers that don’t have a lot of space. This model works great in confined spaces. Plus, the battery that powers this model lasts up to eight to ten hours between charges. So use this solution all day before you need to recharge the batteries. This equipment is always in stock.

How Pallet Inverters Can Help Your Business

They can help to reduce the risk of broken pallets, increase load capacity, and make it easier to rotate and turn them. This can be especially useful for businesses that handled every type of supports. Let’s delve deeper into how these invaluable tools can contribute to the success of your manufacturing processes.

1. Enhanced Load Integrity:

One of the primary advantages is their ability to reduce the risk of broken pallets. The precise and controlled inversion process ensures that pallets are handled with care, minimizing the chances of damage during transfers.

Preserve Product Integrity, Save Costs

This not only preserves the integrity of your products but also reduces the need for frequent pallet replacements, translating to cost savings over time.

2. Increased Load Capacity:

A stationary pallet inverter can maximize business’ load capacity. By efficiently repositioning pallet loads, these machines ensure optimal use of storage space and transportation resources.

Cost-Efficient Shipping Solutions

This can lead to significant cost efficiencies, as you can transport more goods in each shipment, ultimately reducing the number of trips and associated expenses.

3. Improved Maneuverability:

The ability to rotate and turn pallets with ease is a distinctive feature of pallet inverters. This functionality proves invaluable for businesses dealing with a variety of product types and support structures.

Flexibility for Diverse Handling Needs

Whether you’re handling fragile items, irregularly shaped products, or different pallet sizes, pallet inverters provide the flexibility needed to navigate these challenges seamlessly.

4. Streamlined Operations:

Integrating a pallet exchanger solution into your manufacturing processes can streamline operations by expediting the pallet handling and transferring goods.

Efficiency Through Automation: Boosting Productivity and Safety

The automation and precision offered by a stationary pallet inverter contribute to a more efficient workflow, reducing manual labor requirements and minimizing the risk of human error. This not only boosts productivity but also enhances overall operational safety.

5. Versatility Across Industries:

From food and beverage to pharmaceuticals, automotive, logistics, and more, businesses with diverse operational needs can benefit from the adaptability of pallet inverters.

Versatility for Future-Proof Material Handling

The ability to cater to different sectors makes these machines a valuable investment for companies looking to future-proof their material handling processes.

Transform Your Operations: Pallet Inverters for Efficiency and Innovation

Incorporating these solutions into your business’s material handling strategy can yield substantial benefits. From safeguarding product integrity to optimizing load capacity and streamlining operations, these machines contribute to a more efficient and cost-effective manufacturing ecosystem.

Strategic Innovation: Pallet Inverters for Industry Adaptability

As technology continues to advance, exploring innovative solutions like stationary pallet inverters becomes a strategic move for businesses aspiring to stay competitive and adaptable in their respective industries.

How to handle Slip Sheets with our Pallet Inverter

Slip sheets are an important component that our pallet exchanger are capable of handling. These supports are used to separate the pallet load from the pallet itself, as they take up less space in the warehouse and during shipments.

Seamless Slip Sheet Handling with Our Pallet Inverters

Handling slip sheets with our pallet inverters is a seamless process that adds an extra layer of versatility to your material handling capabilities. Here’s a closer look at how our innovative solutions adeptly manage slip sheets:

Efficient Separation Process:

They are specifically designed to handle slip sheets with precision and efficiency. The machinery is equipped to delicately separate the pallet load from the slip sheet, ensuring a smooth transition without compromising the integrity of your products. This meticulous separation process contributes to maintaining the quality of your goods during handling and transportation.

Space Optimization:

Slip sheets offer a space-saving alternative by occupying less room in both the warehouse and during shipments. Our machines enhance this advantage by facilitating the seamless transfer of pallet loads onto slip sheets and vice versa. This space optimization not only contributes to a more organized and efficient warehouse but also translates to potential cost savings in terms of storage and transportation expenses.

Streamlined Handling of Various Supports:

The adaptability of our pallet inverters extends to the diverse types of supports your business may encounter. Whether you’re working with traditional pallets, slip sheets, or a combination of both, our machines are engineered to handle these variations effortlessly. This flexibility in accommodating different support structures adds a layer of convenience to your material handling processes.

Customized Solutions for Your Business:

Recognizing that every business has unique requirements, our pallet inverters are designed to offer customized solutions. Whether you need specific configurations for slip sheet handling or adjustments to accommodate different load sizes, our team works closely with you to tailor the functionality of the pallet inverters to align seamlessly with your operational needs.

Enhancing Workflow Efficiency:

By integrating slip sheet handling capabilities into our pallet inverters, we aim to enhance the overall efficiency of your workflow. The automation and precision of these machines contribute to faster and more streamlined operations, reducing manual effort and minimizing the risk of errors. This, in turn, allows your workforce to focus on higher-value tasks, contributing to increased productivity.

In summary, our pallet inverters go beyond conventional material handling solutions by adeptly managing slip sheets. From efficient separation processes to space optimization and customized solutions, these machines add significant value to businesses seeking versatile and efficient material handling solutions. Explore the possibilities of elevating your operational efficiency with our pallet inverters tailored for slip sheet handling.

The Benefits of Using a Pallet Inverter

By using them, is possible to reduce broken or damaged product. There are some pallet inverters machines that are designed to handle one pallet at a time, allowing for precise control over the load.

Custom Builds and Model Numbers

At Topindustries Inc. we offer a wide range of models, each with different load capacities and features. We also offer the option for custom builds, allowing businesses to have specific solution for safely replace and handle their products.

Free Standing and 180 Degree Rotation

All of our pallet inverters machines are dual clamps free-standing with 180 degree rotation, meaning they do not need to be anchored at ground level or attached to any other equipment.

Advanced Features of our Pallet Inverter

Our pallet inverters are designed with advanced features that make material handling even easier and faster. For example, the “Game Changer” is designed with dispensers that allow for seamless and fully automated loading and unloading processes. This innovative equipment is engineered to optimize efficiency and productivity, while reducing the need for manual labor.

Reducing Product Damage with Rotators

One of the key features is the advanced pallet rotator. With the ability to rotate the load 180 degree, the pallet rotator help to reduce product damage by allowing for easy access to all sides of the load. This is especially useful for those that need to inspect or exchange pallets before shipment. They are suited for forklift.

Custom Builds for Unique Needs

We understand that every business has unique material handling needs, that’s why we offer the option for custom build the pallet rotator. By working with our team, is possible to have a pallet inverter built to specific needs, including custom load capacity and advanced features such as faster handling and dispensers.

Flexibility and Convenience

For example, the portable “Turner 3300” is designed to be free standing, meaning you don’t need to be anchored to the ground or attached to any other equipment. This allows for easy movement in any area of your facility. It’s very similar to a forklift:

The Importance of Pallet Exchange

This exchange is an important aspect in the every distribution center or factory. Our premier pallet inverters are designed to make this process as easy and efficient as possible. For example, by using a rental pallet, you can safely replace hygienic pallets by recuding costs and minimize the risk of broken pallets. Our solution are often in service for rotating wood materials, bottles, bags, or boxes.

How our Pallet Inverter Can Help to Reduce Damaged Goods

Damaged goods can have a significant impact on a company’s bottom line, and our pallet inverters are designed to help reduce this risk. By using a Top Industries’s solution, you can improve the material handling processes by speeding up the products flow in the production deparment and save on shipping and trasports.

The Advantages of Using Plastic Onces

They are becoming increasingly popular in the material handling due to its durability and resistance to moisture, insects, and chemicals. Our pallet flippers are designed to handle various types of supports, including those below, making it easier for businesses to switch them.

Choosing the Right Pallet Inverter Model

Choosing the right model for your business is essential to ensure that you are getting the right one for safely lifting your load. Our wide range of models are capable of handling different load types and features. We can also stack your supports.

Improve Your Loading and Unloading Process

Loading and unloading pallet loads can be a time-consuming and labor-intensive task, but our pallet rotator is designed to make this process more efficient and easier. By using one of these equipments, businesses can reduce the risk of broken items and increase the product flow capacity. This can be especially useful for a company that handle high weight loads on a daily basis.

Equipment of Pallet & Product Handling

Here’s a bulleted list of pallet inverter:

-

Mobile pallet Inverter;

-

Portable pallet inverter (also no product tilting);

-

Semi Automatic Pallet inverter;

-

Automatic Pallet Inverter;

-

Fully Automatic Pallet Inverter;

The Advantages of Using Wooden Pallets

While plastic pallets are becoming increasingly popular, these supports are still widely used in the product handling. They are often more affordable than plastic onces and can be easily repaired if they become damaged. Our pallet flippers are designed to handle various types of supports. Additionally, they are often more environmentally friendly as they can be recycled or repurposed after use.

How our Pallet Inverter Improves your warehouse

Pallet turners are a valuable tool for any service or distribution center that handles pallet loads. They can help to reduce the risk of damaged products, increase the material flow, and make it easier to rotate and turn loads. Our pallet turners can be especially useful for businesses that use wood or plastic pallets and need to exchange them before they enter into the factory.

Understanding the benefits of a pallet inverter for material handling

The Importance of Slip Sheets in Your Supply Chain

Slip sheet is an important component and tool and doesn’t affect the capacity. A slip sheet is used to separate the pallet load from the pallet itself, allowing for easier rotating, inverting, and turning of the load.

In Pharmaceutical and Food Industries

As a warehouse manager in the pharmaceutical and food sector, you are responsible for reducing product damage. Premier pallet inverters can play an important role in achieving these goals. They are designed to make material handling easier, more efficient, and safer, while also reducing damaged goods and saving, replace or shipping supports.

How Rotators Can Improve Efficiency

Efficiency is crucial in the these kind of storage, where time is of the essence. Our premier pallet systems are equipped with pallet rotators, which can rotate the pallet load 180 degree, making it easie for the manufacturer in the production department to access all sides of the load for inspection or packaging. This can significantly improve the efficiency of the product handling process, and reduce the risk of a damaged product.

The Advantages of Using Plastic Pallets

In the pharmaceutical sector, plastic pallet is becoming increasingly popular due to their durability and resistance to moisture, insects, and chemicals. For example the “Hands-Free” is the ideal choise as it is designed to handle various types of supports. Additionally, a single plastic pallet is often more lightweight than a single wood pallet, making them easier to handle and shipping, which can also help to reduce the risk of damaged goods.

How Pallet Turners Can Improve Safety

Pallet turners is only one type of more than 50 different pallet exchanger in our production range. Pallet Inverter can help to increase an easy load transfer, increase load handling, and make it easier to rotate and turn supports.