Are you looking for ways to improve your warehouse productivity? Have you considered using a pallet inverter? Pallet inverters are an innovative solution for businesses looking to streamline their operations and increase efficiency. In this article, we will explore the benefits of using pallet inverters and how they can help increase productivity in your warehouse.

Understanding the Role of Pallet Inverters in Improving Productivity

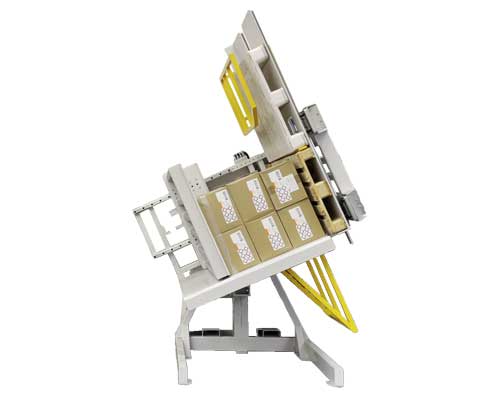

Pallet inverters are machines that are used to rotate or flip pallets, allowing goods to be loaded and unloaded more efficiently. They are especially useful when dealing with damaged or irregularly shaped pallets that cannot be moved easily by forklifts. By using pallet inverters, businesses can increase productivity by reducing the time and effort required to move goods around their warehouse.

The Benefits of Using Pallet Inverters in Warehouses

One of the main benefits of using pallet inverters is increased efficiency. By using pallet inverters, businesses can save time and reduce labor costs, as they can quickly and easily flip pallets without the need for manual labor. This means that employees can focus on more value-added tasks, such as managing inventory and fulfilling orders.

Another benefit of using pallet inverters is improved safety. Pallet inverters can help reduce the risk of workplace injuries by eliminating the need for manual labor and reducing the risk of strains and sprains. Additionally, pallet inverters can help prevent product damage by ensuring that goods are loaded and unloaded safely and efficiently.

Improved Safety and Reduced Labor Costs with Pallet Inverters

By reducing the need for manual labor, pallet inverters can help businesses reduce labor costs and improve workplace safety. With pallet inverters, employees no longer need to manually rotate or flip pallets, reducing the risk of injury and fatigue. Additionally, pallet inverters can help prevent product damage by ensuring that goods are loaded and unloaded safely and efficiently.

What are the safety considerations when using a pallet inverter

Choosing the Right Pallet Inverter for Your Business Needs

When selecting a pallet inverter, it’s important to consider your business needs and the types of pallets that you will be handling. Factors to consider include the size and weight of the pallets, the number of pallets that you need to handle, and the frequency of pallet flips.

Which are the most common types of pallet inverters

Factors to Consider When Selecting a Pallet Inverter

Some other factors to consider when selecting a pallet inverter include the level of automation required, the available space in your warehouse, and the required level of customization. Top Industries Inc., a leading manufacturer of pallet inverters, offers a wide range of pallet inverters that can be customized to meet your specific business needs.

Investing in Pallet Inverters for Long-Term Cost Savings

While the initial investment in pallet inverters may seem high, they offer significant long-term cost savings. By reducing labor costs and increasing efficiency, businesses can see a return on investment (ROI) within a short period of time. Additionally, pallet inverters can help businesses reduce product damage, which can result in further cost savings.

Which factors affect the cost of a pallet inverter?

The Return on Investment (ROI) of Pallet Inverters

The ROI of pallet inverters depends on several factors, including the size and scale of your business, the types of pallets that you handle, and the frequency of pallet flips. However, studies have shown that businesses can see a ROI within as little as 12-18 months of implementing pallet inverters. Over time, businesses can continue to see cost savings and increased productivity, making pallet inverters a worthwhile investment.

In conclusion, using pallet inverters can significantly increase productivity in your warehouse, reduce labor costs, and improve workplace safety. When selecting a pallet inverter, it’s important to consider your business needs and the types of pallets that you will be handling. With the right pallet inverter, businesses can see a return on investment within a short period of time and continue to see cost savings and increased productivity over the long term. Contact Top Industries Inc. today to learn more about our pallet inverters and how they can benefit your business.

Pingback: What is the purpose of a pallet inverter? - Pallet Changer - Top Industries