People Also Ask

The main difference is that a supply chain is a series of steps involved in getting a product to consumers, while an integrated supply chain involves seamless coordination among suppliers, manufacturers, and distributors for optimized efficiency and communication.

An integrated supply chain is vital because it streamlines processes, reduces costs, improves communication, enhances product traceability, and provides a holistic view, ultimately boosting efficiency and competitiveness for businesses.

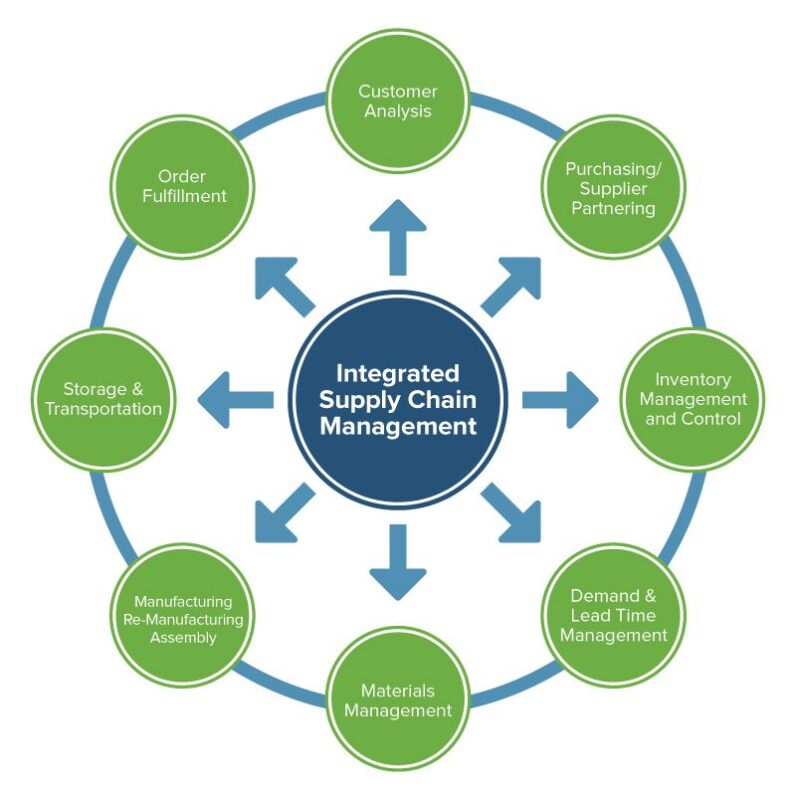

The key elements of an integrated supply chain are information sharing, coordinated processes, reduced redundancy, advanced technologies, and synchronized logistics across suppliers, manufacturers, and distributors.

The 4 C’s of the integrated supply chain are Coherence, Collaboration, Connectivity, and Customer.

The 4 elements of supply chain integration are Internal Integration, Supplier Integration, Customer Integration, and External Integration.

A well-tuned supply chain, woven together by a network of suppliers, manufacturers, and distributors, dances in harmonious coordination. Their mission: to execute the warehousing and distribution of goods with maximum efficiency.

This interconnected supply chain thrives in the digital realm, where processes are seamlessly synchronized. It acts as the conductor, orchestrating the efforts of companies engaged in product conception, manufacturing, and promotion. Within this symphony of logistics, the introduction of Warehouse Management Systems (WMSs) plays a pivotal role, enabling the fluid exchange of information between logistics hubs and production centers.

What is an integrated supply chain process?

An integrated supply chain comes alive when its diverse operations harmonize, including tasks like sourcing raw materials, crafting product designs, manufacturing, warehousing, and distribution.

Per the wisdom of the National Academies of Sciences, Engineering, and Medicine, an integrated supply chain represents a dynamic partnership between customers and suppliers. United by savvy management techniques, they collaborate to optimize their collective prowess in birthing, disseminating, and nurturing the lifecycle of a final product.

At the heart of an integrated supply chain beats the rhythm of product traceability. It’s akin to tracking the life story of a product, from its inception through production and distribution. Thanks to the symphony of synchronized operations, each link in the supply chain knows precisely where every raw material, semi-finished good, or finished product resides, and the precise conditions under which each transformation occurred.

Integration can take on multiple forms, including the acquisition or fusion of other companies to expand services or the cultivation of new business fronts that encompass more stages of the supply chain. This strategic dance unfolds in two ways:

Horizontal Integration:

Picture a soft drink distributor acquiring a regional rival to broaden its market reach and tighten its grip on pricing—a classic example of horizontal integration.

Vertical Integration:

This is akin to a business extending its embrace across multiple tiers of the supply chain. For instance, a software company may acquire a UX (user experience) firm to streamline costs and assert control over additional levels of the supply chain, creating a symphony of synergy.

4 benefits of supply chain integration

Embracing an integrated supply chain entails a symphony of information exchange, where every facility the product encounters shares its processes and operations. Within this harmonious communication web among supply chain links, the following benefits come to life:

-

Cost Elimination:

The supply chain integration maestro orchestrates a reduction in costs by trimming superfluous steps—farewell to redundant vendors and bloated inventories. Swift material flow between supply chain tiers minimizes the expense of stockpiling.

-

Enhanced Logistics and Production:

The elimination of excess suppliers leads to seamless coordination, diminishing supply chain costs and errors.

-

Product Traceability:

Integration weaves a narrative of product history, as stakeholders access complete information on raw material batches, production conditions, storage, and shipping. It’s a traceable journey from inception to delivery.

-

Holistic, Customer-Centric Vision:

Integrated companies enjoy an encompassing view of logistics and production processes, guiding decisions aligned with business needs, all thanks to precise information.

Now, let’s explore the path to supply chain integration:

Consulting firm Grant Thornton’s 2020 Digital Supply Chain Survey unveils a striking statistic: a mere 17% of surveyed executives had integrated supply chains in 2020. The report underscores the transformative role of digitization: “The digital opportunity is clear. New technologies and innovative digital strategies can help transform manufacturing industry supply chains to make them more efficient, more responsive, more agile, and more competitive.”

Process digitization becomes the glue that fosters coordination among supply chain tiers. It paves the way for seamless information transfer between warehouses and production centers through which the product journeys. The adoption of digital solutions, such as warehouse management software or enterprise resource planning (ERP) systems, emerges as a cost-cutting mechanism, eliminating unnecessary stages.

Integral to an integrated supply chain is the sharing of information across numerous operations: supply logistics, production line planning, inventory management, order distribution, and customer service, evalutating the acquisition of pallet inverters among others. This visibility isn’t limited to company departments; it extends to production and logistics managers. The integration of various tiers equips these managers with real-time information on product states and storage conditions, empowering them to enhance the quality of the logistics service.

Software for supply chain integration

The symphony of supply chain integration enhances the quality of the end product or service. As noted by the authors of “Supply Chain Integration Capability: An Organizational Routine Perspective,” it involves strategically collaborating and cooperating with supply chain members. This boosts the flow of products, services, information, money, and decisions, achieving a coordinated management of intra and inter-organizational processes. Efficiency and effectiveness shine as the end result.

Elevating your supply chain into a seamless and efficient orchestra demands the conductor’s baton of warehouse management software. These sophisticated tools orchestrate the flawless transmission of information throughout the supply chain, harmonizing every stage of a product’s journey and minimizing errors.

At the heart of this symphony lies the Warehouse Management System (WMS), a pivotal tool for supply chain integration. WMS plays the role of the maestro, orchestrating seamless information exchange with other software programs involved in the logistics management of a product, be it the company’s own systems or those of partnering organizations. This harmonious collaboration not only improves information sharing but also automates tasks for greater efficiency.

As we delve into the digital realm, warehouse management software like Easy WMS takes center stage, acting as the bridge to synchronize information with other vital programs utilized in the supply chain. These include Enterprise Resource Planning (ERP) systems, whether within the company or at other supply chain links, Manufacturing Execution Systems (MES), and Transportation Management Systems (TMS). Beyond their individual logistics capabilities, these applications harmonize information flow between supply chain tiers, nurturing product traceability and enhancing overall operational effectiveness.

Easy WMS, the virtuoso of warehouse management systems, features specialized modules designed to orchestrate seamless supply chain integration. Consider the Multi Carrier Shipping Software, a powerful instrument for fostering smooth communication between your company and transportation agencies. Another remarkable module, the Marketplaces & Ecommerce Platform Integration, orchestrates a harmonious synchronization of the catalogs of various online sales channels with real-time warehouse stock data. This virtuoso performance eliminates order management errors and refines inventory control, ensuring that your supply chain symphony hits all the right notes.

Integrated supply chain for efficient warehousing

Sharing information flows with the rest of the links in the supply chain minimizes the risk of error in inventory management, product manufacturing, and order fulfillment. This is why more and more companies are investing in digital solutions that foster the integration of all links in the supply chain.

Software such as Easy WMS from Mecalux syncs information on warehouse operations with other logistics centres, with other programs within the same organization, and even with different types of software programs belonging to other supply chain participants. Want to be part of an integrated supply chain? Don’t hesitate to contact us. One of our expert consultants will work with you to come up with the best digital solution for your warehouse.

Pingback: Cycle Stock: The Complete Explanation