Applications of Pallet Flippers

Pallet flippers are widely used in various industries such as food and beverage, pharmaceuticals, and automotive. In the food and beverage industry, they are used to handle delicate products such as glass bottles, jars, and cans. In the pharmaceutical industry, pallet inverters are used to handle products that require strict hygiene standards.

In the automotive industry, pallet exchanger are used to handle heavy components and parts. They can also be used in other industries such as warehousing, distribution, and logistics.

Benefits of Using a Pallet Flipper

Using a pallet flipper for material handling has several benefits, including increased efficiency, improved safety, and reduced labor costs. Pallet flippers can flip pallet loads in seconds, which significantly reduces the time and labor required to handle pallets manually.

Advantages of Using a Pallet Flipper in Material Handling

Using a pallet inverter also reduces the risk of injuries and accidents associated with manual pallet handling, thus improving workplace safety. In addition, pallet flippers can be customized to suit specific applications, making them a cost-effective solution for material handling needs.

Customizable Options for Pallet Flippers

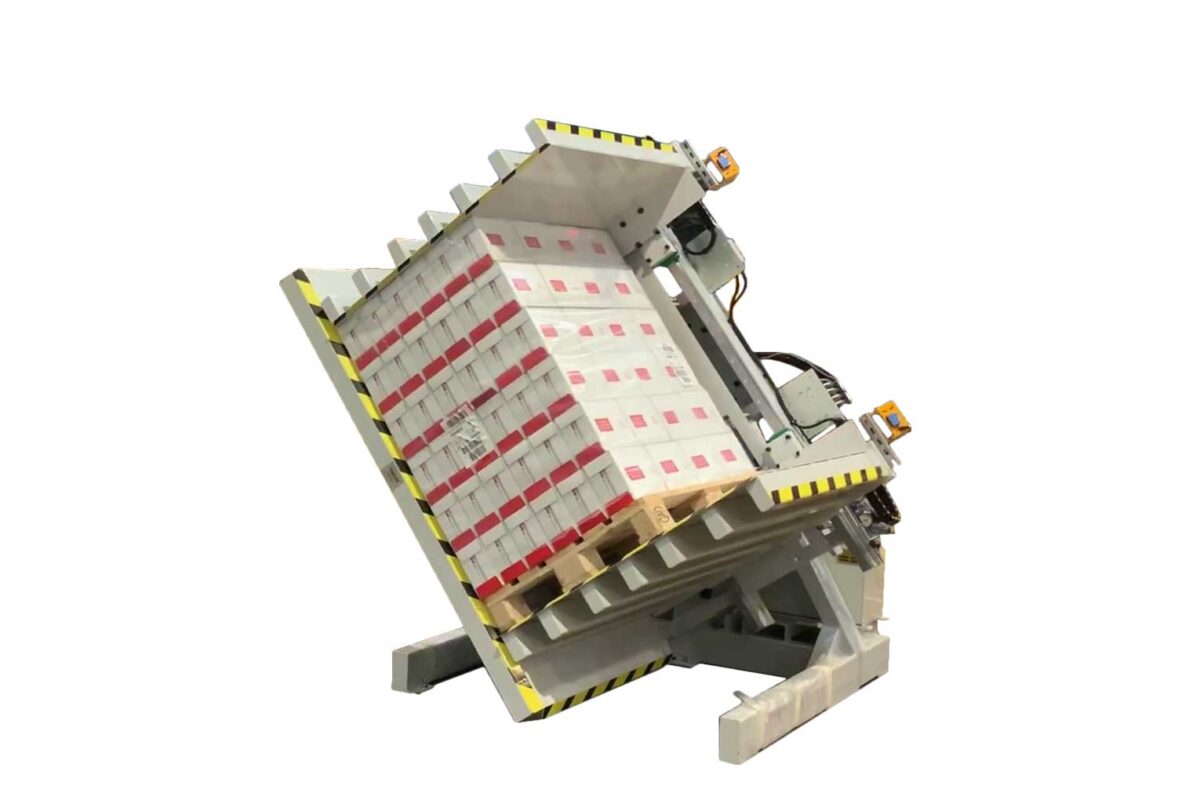

Pallet flippers come in various sizes and configurations to suit different applications. Some pallet inverters are designed to handle standard pallet sizes, while others can handle custom sizes. Some pallet flippers can also handle different types of pallets, including wood, plastic, and metal. In addition, pallet flippers can be customized with various features such as safety guards, conveyor systems, and automation systems.

Choosing the Right Pallet Flipper

Choosing the right pallet inverter depends on several factors, including the type of load, pallet size, and application requirements. At Top Industries Inc., we offer a wide range of pallet flippers designed to meet different material handling needs. Our experienced team can help you select the right pallet flipper for your specific application, ensuring maximum efficiency and safety.

Maintenance and Care for Pallet Flippers

Proper maintenance and care are essential to ensure the longevity and performance of pallet flippers. Regular inspections and maintenance can help prevent breakdowns and downtime, which can result in costly repairs and lost productivity. At Top Industries Inc., we offer maintenance and repair services for pallet exchangers, ensuring that your equipment is always in top condition.

The Ease of Use and Maintenance of a Pallet Flipper

Trust Top Industries Inc. for Your Pallet Exchanger Needs

Top Industries Inc. is a leading manufacturer of pallet flippers and other material handling equipment. Our products are designed and manufactured with precision engineering and high-quality materials to ensure maximum durability and performance. We also offer customization options, maintenance services, and expert support to help you get the most out of your equipment.

The Durability and Longevity of a Pallet Flipper

Trust Top Industries Inc. for all your pallet exchanger needs and experience the difference that quality and innovation can make.

Conclusion

In conclusion, pallet inverters are a versatile solution for material handling needs in various industries. They offer several benefits, including increased efficiency, improved safety, and reduced labor costs. Choosing the right solution and maintaining it properly can help ensure maximum performance and longevity.

At Top Industries Inc., we offer a wide range of pallet flippers and support services to help you get the most out of your equipment. Contact us today and get a quote!