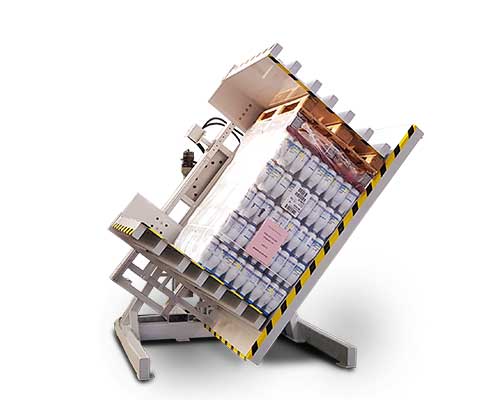

As a leading provider of material handling equipment, Top Industries Inc is proud to offer our customers the latest in automation technology. Our pallet flipper is a prime example of how automation can improve efficiency and reduce maintenance costs for businesses of all sizes.

The Ease of Use and Maintenance of a Pallet Flipper

At Top Industries Inc, we understand that businesses are constantly looking for ways to streamline their operations and increase productivity. That’s why we developed different types of pallet flippers, innovative solutions for the safe and efficient handling of pallets.

Advantages of Using a Pallet Flipper in Material Handling

Our pallet flipper is incredibly easy to use, with a simple push-button operation that allows for quick and easy flipping of pallets. With its intuitive design, it can be operated by just one person, reducing the need for extra labor and freeing up valuable resources for other tasks.

But what really sets our pallet flipper apart is its low maintenance requirements. With its rugged construction and durable components, it is built to withstand the rigors of heavy use without breaking down or requiring costly repairs.

In fact, our pallet inverter is virtually maintenance-free, with no need for oil changes, belt replacements, or other routine upkeep. This not only saves businesses money in the long run, but it also minimizes downtime and ensures that operations can continue uninterrupted.

Automation for Unprecedented Efficiency

One of the biggest advantages of our pallet flipper is the level of automation it provides. With its advanced features and capabilities, it can greatly enhance the efficiency of any operation.

For example, our pallet inverter can be programmed to automatically adjust to different pallet sizes, eliminating the need for manual adjustments and reducing the risk of errors. It can also be integrated with other material handling equipment, such as conveyors and forklifts, to create a fully automated system that can handle even the most complex tasks.

How to Improve Efficiency with a Pallet Flipper

By automating these processes, businesses can reduce the amount of time and labor required to move materials, while also increasing accuracy and reducing the risk of injury or damage to products.

Optimizing Material Handling with Top Industries Inc’s Pallet Flipper

At Top Industries Inc, we are committed to providing our customers with the latest in automation technology. Our pallet inverter is just one example of how our innovative solutions can help businesses of all sizes streamline their operations, reduce maintenance costs, and improve overall efficiency.

The Importance of a Pallet Flipper in Automating Pallet Flipping Processes

With its ease of use, low maintenance requirements, and advanced automation capabilities, our pallet exchanger is the ideal solution for any business looking to optimize their material handling processes. Contact us today to learn more about how our pallet flipper can benefit your business.