One common question that arises in warehouses and distribution centers is whether it’s better to push or pull a pallet.

Should you push or pull a pallet?

The choice to push or pull a pallet depends on factors such as load orientation, workspace layout, ergonomics, floor conditions, load stability, equipment, and workplace policies.

The choice between these two methods can significantly influence the workflow and overall productivity. In this article, we will explore the factors to consider when deciding whether to push or pull a pallet, helping you make informed choices in your material handling operations.

Load Orientation:

The orientation of the pallet load can greatly influence whether you should push or pull. When the majority of the weight is towards the front of the pallet (the side facing you), it’s often more manageable to push the pallet. Conversely, if the weight is towards the back, pulling may be a better option.

Workspace Layout:

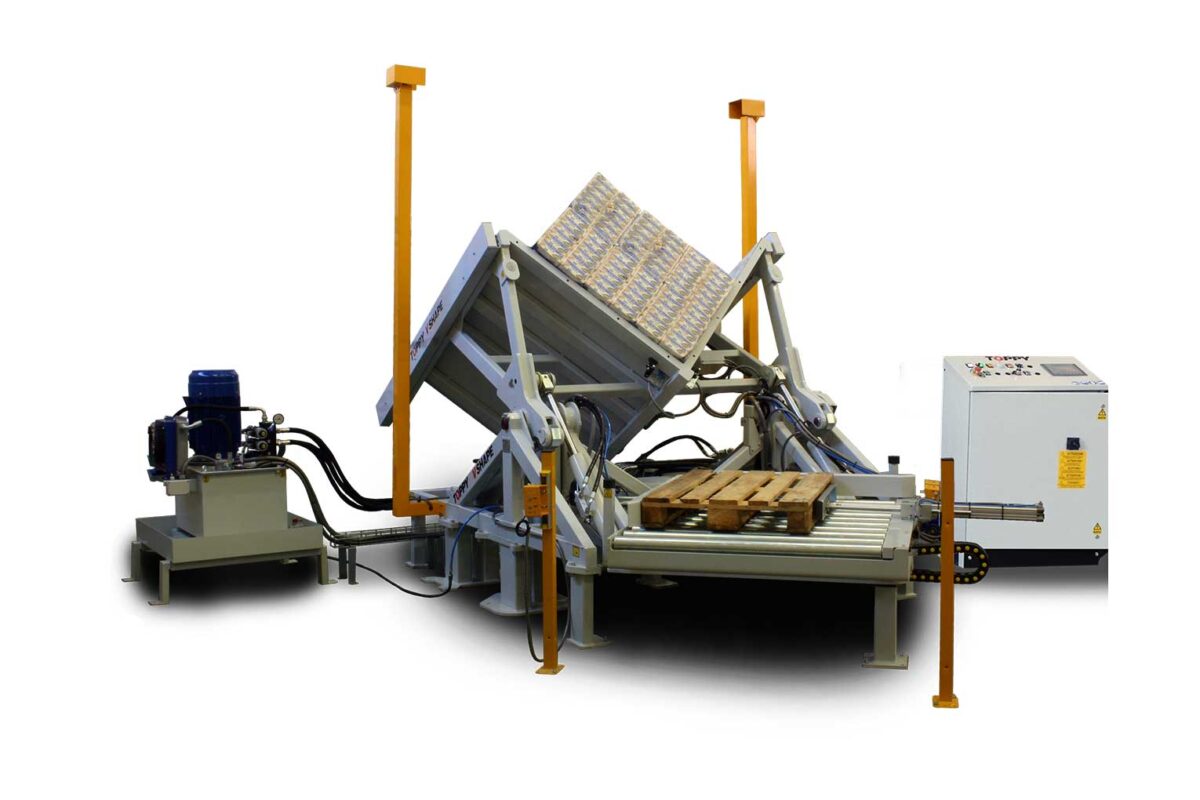

The layout of your workspace and the available maneuvering space can impact your decision. Pushing may be preferable in areas with more open space, (with a pallet transfer equpment) while pulling might be necessary in tight corners or narrow aisles.

Ergonomics and Safety:

Consider the ergonomics and safety of your material handlers. Pushing a pallet may be easier on the back and shoulders, as it allows the operator to maintain better posture. However, pulling might be necessary when navigating ramps or inclines.

Pallet Inverter safety tips and best practices

Floor Conditions:

The condition of the floor can play a role in your choice. Smooth, even surfaces are more suitable for pushing, while rough or uneven terrain may require pulling to maintain stability.

What are the safety considerations when using a pallet inverter?

Load Stability:

Evaluate the stability of the load. If the load is prone to shifting or if there’s a risk of items falling off the pallet, pulling may offer better control and prevent accidents.

Equipment and Tools:

The type of equipment and tools available can also influence your decision. Some material handling equipment, such as pallet jacks, are designed for either pushing or pulling, while others may offer versatility for both methods.

Workplace Policies and Training:

Ensure that your material handlers are trained in both pushing and pulling techniques and that your workplace policies align with safe practices.

Conclusion:

The decision to push or pull a pallet should be based on a careful assessment of various factors, including load orientation, workspace layout, ergonomics, floor conditions, load stability, available equipment, and workplace policies. By considering these factors and providing proper training, you can optimize your material handling operations with pallet inverters, enhance efficiency, and prioritize the safety of your workers.

When it comes to deciding whether to push or pull a pallet, there is no universal solution. The choice should be made on a case-by-case basis, ensuring that the method selected aligns with the specific requirements and conditions of the task at hand, with the guidance of Top Industries Inc.