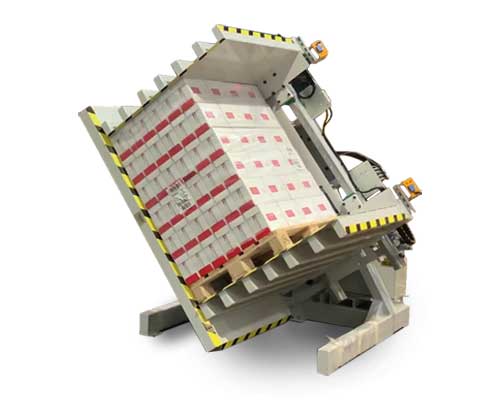

A pallet inverter is an essential tool for maximizing efficiency in your warehouse, but it also poses certain safety risks. It’s important to take steps to minimize these risks and ensure that your employees and products are protected. Top Industries Inc is a leading provider of pallet inverters, and in this article, we will share tips and best practices for pallet inverter safety.

Employee Training

One of the most important steps in ensuring pallet inverter safety is to train your employees. They need to understand how to operate the inverter safely, as well as how to identify and address any potential safety hazards. Top Industries Inc provides comprehensive training for your employees, so they can be confident in their abilities and work safely.

Regular Maintenance

Regular maintenance is crucial for ensuring the safety of your pallet inverter. This involves cleaning, inspection, and repair as needed, to ensure that the inverter is working properly and that any potential safety hazards are identified and addressed. Top Industries Inc offers comprehensive maintenance services, so you can be confident that your inverter is in good hands.

Undestanding the benefits of a pallet inverter for material handling

Safety Equipment

In addition to employee training and regular maintenance, it’s important to have the right safety equipment in place when using a pallet inverter. This may include safety guards, backup power sources, and emergency shut-off switches. By having the right safety equipment, you can minimize the risk of workplace accidents and ensure that your employees and products are protected.

Employee Safety

One of the key factors in pallet inverter safety is employee safety. This involves taking steps to minimize the risk of workplace accidents, such as providing training, wearing personal protective equipment, and implementing safety procedures. Top Industries Inc can help you develop a safety program to ensure that your employees are protected.

Product Safety

In addition to employee safety, it’s important to consider the safety of your products when using a pallet inverter. This involves taking steps to minimize the risk of product damage, such as using the correct pallet size, securing products securely, and avoiding overloading the inverter. Top Industries Inc can help you choose the right inverter for your needs and provide guidance on best practices for product safety.

Monitoring Performance

Finally, it’s important to monitor the performance of your pallet inverter to ensure that it’s working as it should. This involves tracking metrics such as productivity, safety, and efficiency. By monitoring performance, you can identify any areas for improvement and make the necessary changes to ensure that your pallet inverter is working safely and efficiently.

Maximizing efficiency with a pallet inverter in your Warehouse

In conclusion, pallet inverter safety is an important consideration when implementing a pallet inverter in your warehouse. By taking steps to minimize safety risks, you can ensure that your employees and products are protected. Top Industries Inc is a leading provider of pallet inverters, and their tips and best practices can help you get started.