If you work in the manufacturing or logistics industries, you know how important pallets are for storing, moving, and shipping products. However, manually flipping pallets can be a dangerous and physically demanding task for workers. Fortunately, pallet flippers provide a solution that not only improves safety but also enhances ergonomics in the workplace. In this article, we’ll explore the impact of pallet flippers on safety and ergonomics and how Top Industries Inc.’s pallet inverters can help businesses achieve these benefits.

What is a Pallet Flipper?

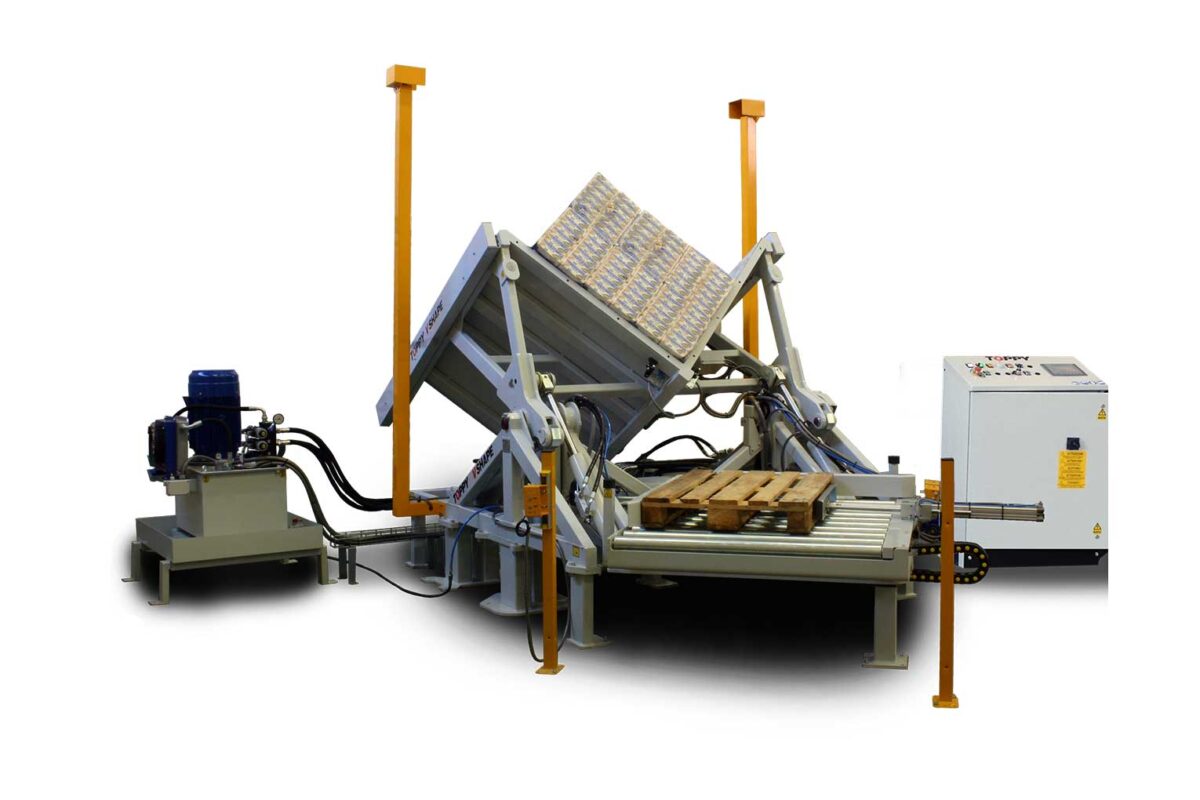

Before we delve into the impact of pallet flippers, let’s define what they are. A pallet flipper, also known as a pallet inverter, is a machine that rotates pallets so that the products they hold can be transferred to a new pallet. The process is efficient, fast, and safe. Manual pallet flipping, on the other hand, can pose risks to worker safety and lead to musculoskeletal disorders (MSDs) due to the repetitive and strenuous activities involved.

Advantages of Using a Pallet Flipper in Material Handling

Impact on Safety

The risks of manual pallet flipping are well documented. Workers who engage in manual pallet flipping are at risk of overexertion, sprains, and strains. Injuries can occur when workers lift heavy pallets, twist their bodies, or use awkward postures. These injuries can be debilitating and can lead to lost productivity and increased workers’ compensation claims. Pallet flippers mitigate these risks by automating the process, reducing the need for manual labor, and providing safety features that protect workers from accidental operation.

Top Industries Inc.’s pallet inverters offer a range of safety features, including emergency stop buttons, safety interlocks, and photoelectric barriers. These features prevent accidental operation and improve worker safety, reducing the risk of injuries and accidents in the workplace.

Risks of Manual Pallet Flipping

Manual pallet flipping is a physically demanding task that requires workers to engage in repetitive and strenuous activities. Workers who engage in manual pallet flipping are at risk of developing MSDs, such as lower back pain, shoulder pain, and carpal tunnel syndrome. The physical demands of manual pallet flipping can cause wear and tear on the body, leading to long-term health problems.

Pallet Flippers and Worker Safety

Pallet flippers eliminate the need for workers to engage in strenuous lifting and bending, reducing the risk of MSDs and other injuries. Pallet flippers are designed to handle heavy loads safely, reducing the risk of injuries caused by lifting and twisting. By automating the pallet flipping process, workers can focus on other tasks that are less physically demanding, reducing the risk of overexertion.

The Ease of Use and Maintenance of a Pallet Flipper

Impact on Ergonomics

Ergonomics is the study of designing tools and equipment that are safe and comfortable for workers to use. Manual pallet flipping is not an ergonomic task and can cause MSDs due to the repetitive and strenuous activities involved. Pallet flippers, on the other hand, are designed with ergonomics in mind, providing a range of benefits that improve worker health and comfort.

Advantages of Pallet Flipper over Traditional Methods

Conclusion

Pallet flippers have revolutionized the material handling industry by improving worker safety and reducing the risk of MSDs. Top Industries Inc.’s pallet inverters are among the best on the market, offering advanced safety features and ergonomic benefits. By investing in pallet flipping equipment, businesses can improve their material handling operations, increase productivity, and protect their workers from injury.