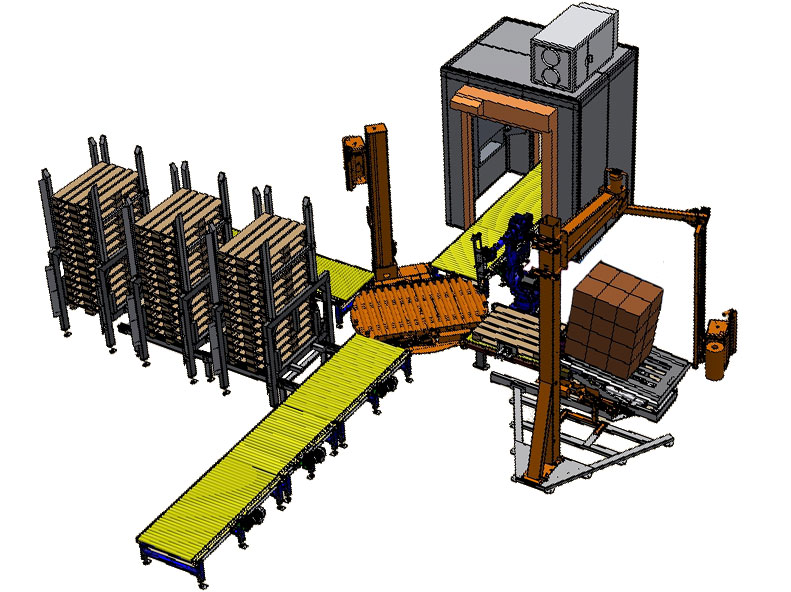

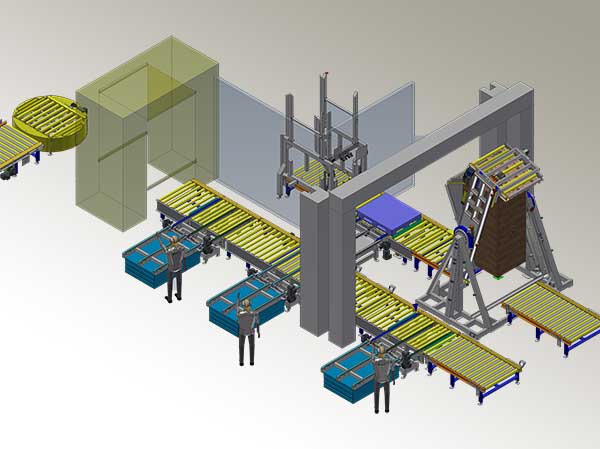

Are you looking for industrial handling equipment? Well… Top Industries Inc is the world leading company for pallet exchangers. Our production range’s include more than 50 different industrial handling solutions. Start from our advanced pallet transfer systems!

When the employees need to move loads fast yet safely pallets are found to be indispensable. Unfortunately, some manufacturers randomly choose pallets without considering the construction, design, and purpose. The benefits and contentment are only assessed. Besides, the workers using the pallet ignore the best practice for using the pallet safely is forgotten, which is not good.

Top Industries are leading manufacturers of industrial handling equipment around the world. We offer an array of pallet inverter or changer models in different versions including stationary, portable, or fully automatic customization systems. Nevertheless, it is the responsibility of the users to handle the pallet properly.

Valuable inventory needs proper handling or it can get damaged via the improper placing of goods or using pallets not designed for a specific load or the pallet is damaged. In pallet performance, load weight and height have to be proportionate to the pallet base to stack them safely.

Wooden pallets get rough and need to be disposed of but you can buy them in different materials like aluminum, plastic, cardboard, and even presswood. Wooden pallets are majorly used but pallets designed from metal or composite material is used in the pharmaceutical, food & beverage, or aviation sector.

Pallets are available in a variety of styles and designs suitable for unique applications, but pallet are managed by industrial handling equipment. Their safe practices have to follow universal guidelines.

Warehouse and shipping companies reduce pallet mishaps by –

- Choosing the appropriate pallet type for the task.

- Train employees to handle the pallets properly and safely.

Companies implements industrial handling equipment

Why companies implements industrial handling solutions:

- Enhances safety – Properly trained staff handles pallets as well as pallet exchangers safely, which reduces accident and injury rates.

- Less handling tool damage – Proper pallet treatment even reduce the risk of damaging handling tools. Damaged pallets jam mechanical equipment, which can result in costly repairs and lessen productivity.

- Operational efficiency – Pallet protection allows them to stay in circulation, so less downtime and better efficiency.

- Lowers maintenance – Properly used pallets need fewer repairs and maintenance.

- Decreases contamination – Regularly cleaned pallets reduce product contamination risks, which can cause rejection or spoilage.

How to use industrial handling equipment

Discover here how to use industrial handling solutions:

- Bulldozing pallets across the floor or warehouse with a pallet truck is a major cause of damage. Sliding the pallets cause friction between the floor and the pallet’s lower surface. Pallets are designed for lifting and moving.

- Improper insertion of pallet truck forklift doesn’t allow distributing load weight appropriately. It is a situation called ‘short-forking’, which can place unnecessary stress on pallet parts. The pallet is designed to share loads evenly and improper placement setbacks this purpose.

- Powered forklifts are big and if the operator approached the pallet too fast there is less time for fork alignment with pallet frame holes. The teeth strike lower and upper platforms causing them to shatter the frame and crush the load.

- The pallet needs to get uniformly loaded for an even distribution of weight. If more weight is placed at one edge or in the center can cause framework collapse because of design limitations.

- Some warehouses fail to secure the pallet loads to bind goods on pallet frames. The common way to secure loaded pallets is stretch wrapping but some facilities even apply strapping and banding.

- Ignoring checking pallets for damages before using them can cause injury or inventory damage.

- Carelessly handling or throwing pallets can compromise the structural integrity of the pallet and even the flooring surface. Wooden pallets are vulnerable to jarring, while plastic ones can easily crack.

- All the unused pallets can be stacked. Many loaded pallets can be stacked in piles. While stacking loaded or unloaded pallets, the operators need to know the proper technique. Misalignment can damage the pallet and even injure the worker.

It is crucial to prevent poor industrial handling equipment practices. It is viable via a worker training program associated with overall pallet use.

Pallet industrial handling equipment guidelines

Discover here the guidelines for industrial handling solutions:

- Never load a pallet beyond its maximum weight capacity.

- Never use a temporarily joined pallet.

- Never exceed the pallet’s outer perimeter footprint.

- Never exceed load height. It has to be the same as the base dimension.

- Understand how the center of gravity functions because the unevenly distributed load can cause the pallet to topple.

Pallet securing guidelines

Failing to secure a pallet is also a big reason for damages. Lighter loads may not need any securing allowing the gravity and friction forces to cooperate. However, it is risky.

- Stretch wrapping is common restraint. It is strong, light, and cost-effective. Don’t just wrap goods that need to be exported but cloak goods to the pallet.

- The strapping and banding method is also used. It entirely depends on pallet types and products to be shipped. Ensure not to extend tension on bands or the pallet frame can get damaged.

- Edge protection is used on compression-sensitive materials like cardboard boxes. Angle brackets are used on pallet frame corners or box edges to prevent tensed strap damages.

Pallet handling guidelines

Most of the accidents [property damage or worker injury] occur because of improper pallet handling. Accidents are preventable via training and education in proper handling techniques.

- Hand pallet trucks and jacks can be risky if incorrectly operated. Operators need official training and certification. Forklift training is compulsory according to OSHA regulations.

- Operators need to wear PPE [proper protection equipment] when they are operating pallet exchangers or pallets.

- Pick pallets awkwardly can cause a strain on your arms. It is sensible to have two workers deal with a single empty pallet.

Pallet maintenance guidelines

- Never use cracked or broken pallets. Check for loose fasteners or nails on wooden and UV ray discoloration on the plastic pallet.

- Sterilize pallets used in the food and Pharmaceutical sector to adhere to FDA rules.

- Remove damaged pallets and mark them as unserviceable.

Workers who handle the pallet and industrial handling equipment need to be competent and familiar with its limitations and purposes.