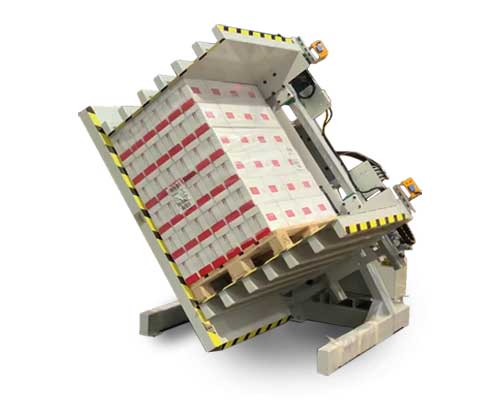

A pallet inverter is a powerful tool for maximizing efficiency in your warehouse. By quickly and easily turning pallets upside down, you can access and work with your products more efficiently, reducing the risk of workplace injuries and enhancing product protection. Top Industries Inc is a leading provider of pallet inverters, and in this guide, we will walk you through the steps involved in implementing a pallet inverter in your warehouse.

Determine Your Requirements

The first step in implementing a pallet inverter is to determine your requirements. You need to consider factors such as the size and weight of your pallets, the type of products you are working with, and the available space in your warehouse. This information will help you choose the right pallet inverter system for your needs, ensuring that you get the best performance and functionality.

Maximizing efficiency with a pallet inverter in your Warehouse

Plan Your Implementation

Once you have determined your requirements, you can then plan your implementation. This involves assessing your warehouse, determining the best location for your inverter, and making any necessary modifications or renovations. You should also consider factors such as power requirements, safety considerations, and employee training.

Install Your Pallet Inverter

Once you have planned your implementation, the next step is to install your pallet inverter. This is a straightforward process, and Top Industries Inc can provide you with a team of experts to ensure that your inverter is installed quickly and efficiently. They will also provide training for your employees, so they can operate the inverter safely and effectively.

Maintain Your Pallet Inverter

Once your pallet inverter is installed, it’s important to maintain it properly to ensure that it continues to perform at its best. This involves regular cleaning, inspection, and repair as needed. Top Industries Inc offers comprehensive maintenance services, so you can be confident that your inverter is in good hands.

Compare pallet inverter models: Which one is right for your business?

Train Your Employees

Training your employees is an important part of implementing a pallet inverter. They need to understand how to operate the inverter safely and effectively, as well as how to perform basic maintenance tasks. Top Industries Inc provides comprehensive training for your employees, so they can be confident in their abilities.

Monitor Performance

Finally, it’s important to monitor the performance of your pallet inverter to ensure that it’s working as it should. This involves tracking metrics such as productivity, safety, and efficiency. By monitoring performance, you can identify any areas for improvement and make the necessary changes to maximize efficiency.

In conclusion, implementing a pallet inverter is a straightforward process that can have a major impact on the efficiency of your warehouse. With the right planning, installation, and maintenance, you can get the best performance and functionality from your inverter. Top Industries Inc is a leading provider of pallet inverters, and their step-by-step guide can help you get started.

Pallet Inverter Safey: Tips and Best Practices