Pallets are an essential component of the logistics industry, used to transport and store goods. Pallets come in different shapes, sizes, and materials, and can be subject to damage during transportation and handling. Pallet damage can lead to product loss, safety hazards, and increased costs. Pallet turners are an effective solution to rotate pallets and prevent damage.

How Pallet Turners Work

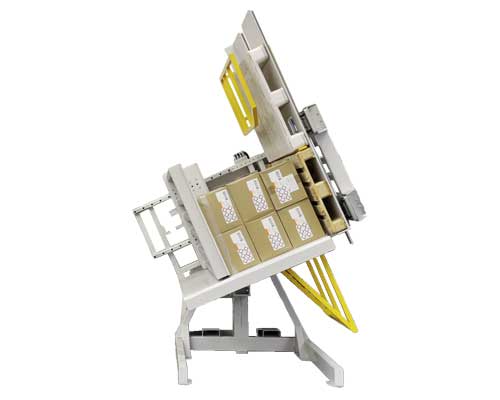

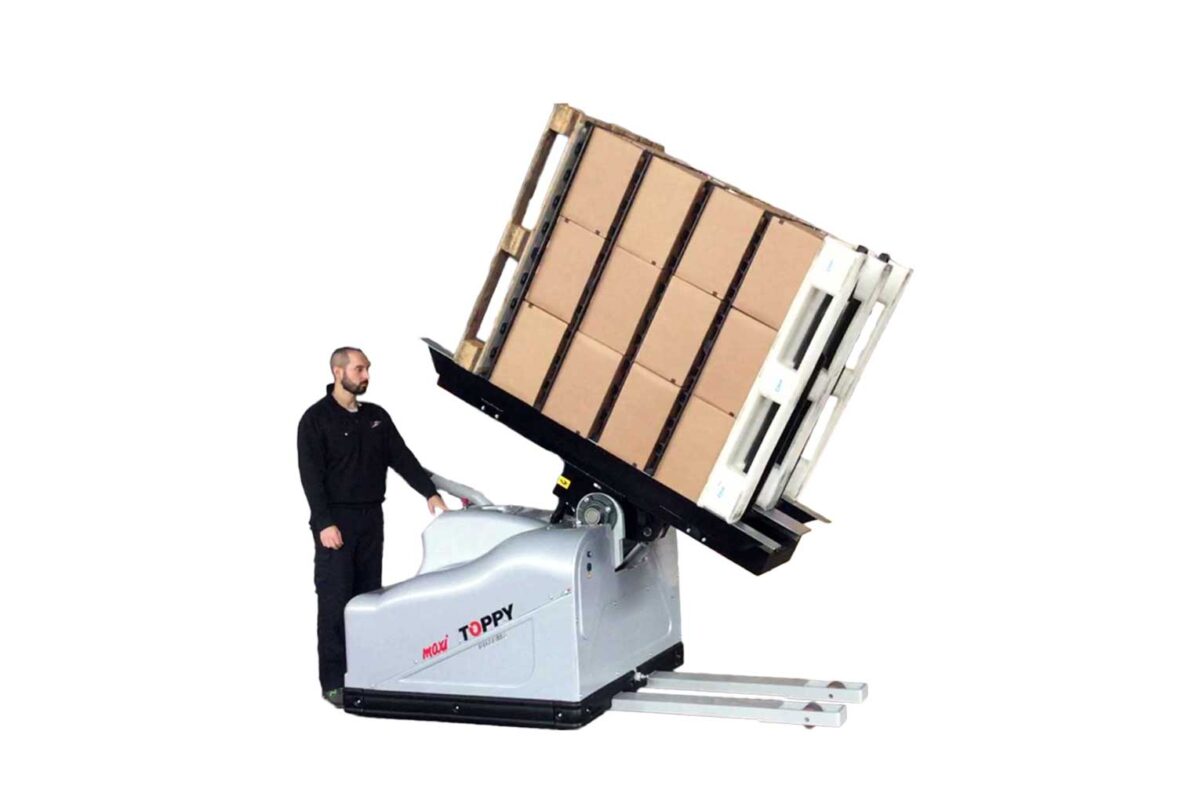

Pallet turners are machines designed to rotate pallets 180 degrees, so that the load on the pallet can be accessed from the opposite side. Pallet turners can handle different types of pallets, including wood, plastic, and metal. Pallet turners can also be customized to handle different sizes and weights of pallets.

Pallet turners typically consist of a rotating platform and a clamping mechanism. The pallet is placed on the platform, and the clamping mechanism secures the pallet in place. The platform then rotates 180 degrees, so that the pallet is upside down, and the load can be accessed from the opposite side. Pallet turners can be operated manually, electrically, or hydraulically, depending on the model.

How Does a Pallet Turner Work a Complete Guide

Benefits of Using Pallet Turners

Pallet turners offer several benefits over traditional pallet handling methods, including:

Preventing Pallet Damage – Pallet turners can rotate pallets without causing damage, reducing the risk of product loss and safety hazards.

Improving Productivity – Pallet turners can rotate pallets quickly and efficiently, reducing handling time and improving productivity.

Reducing Labor Costs – Pallet turners can reduce the need for manual labor, saving costs and reducing the risk of injuries.

Customizable – Pallet turners can be customized to handle different types, sizes, and weights of pallets, making them suitable for a wide range of industries.

How to Choose the Best Pallet Turner for Your Needs

Importance of Preventing Pallet Damage

Pallet damage during rotation can lead to product loss, safety hazards, and increased costs. Damaged pallets can break or collapse, leading to product spillage and waste. They can also cause safety hazards for workers, as they can fall or shift unexpectedly. In addition, damaged pallets can lead to increased costs, as they may need to be replaced more frequently. Preventing pallet damage is essential to ensure safe and efficient operations.

Types of Pallet Damage

Pallets can be subject to different types of damage during transportation and handling. Some common types of pallet damage include:

Cracked or Broken Boards – Pallets can become cracked or broken due to heavy loads, impact, or wear and tear.

Bent or Broken Nails – Nails can become bent or broken, causing instability and potential collapse of the pallet.

Loose Boards – Boards can become loose, leading to instability and movement of the load.

Tips to Prevent Pallet Damage during Rotation with a Pallet Turner

Although pallet turners are designed to prevent pallet damage, there are some best practices to follow to ensure optimal performance:

Choose the Right Pallet Turner – Select a pallet turner that is suitable for your pallets’ size, weight, and material. Top Industries Inc. offers a range of pallet turners that can handle different types of pallets.

Ensure Proper Clamping – Proper clamping is essential to prevent pallet movement during rotation. Make sure the clamping mechanism is secure and adjusted to the pallet’s size and shape.

Inspect Pallets before Rotation – Check for damaged or broken pallets before placing them on the pallet turner. Damaged pallets can break during rotation, leading to product loss and safety hazards.

Best Practices for Safe Use of a Pallet Turner

Conclusion

Pallet turners are an effective solution to prevent pallet damage during rotation. By choosing the right pallet turner, ensuring proper clamping, and inspecting pallets before rotation, you can improve productivity, reduce costs, and increase safety in your operations. Top Industries Inc. offers a range of pallet turners that can meet your pallet handling needs. Contact us today to learn more about our products and services.