In the world of logistics and supply chain management, finding the perfect balance between maintaining ample inventory levels and minimizing costs is an ongoing challenge. This delicate equilibrium is precisely where the EOQ Formula steps in as a beacon of optimization. In this article, we’ll explore the depths of EOQ (Economic Order Quantity) and its impact on cycle stock, unraveling its intricacies and revealing how mastering this formula can transform your business’s logistics efficiency.

What is EQQ and its formula?

The economic order quantity (EOQ) is a strategic calculation aimed at determining the perfect order quantity for businesses. Its goal is to minimize logistics expenses, warehouse utilization, the risk of stockouts, and the burden of overstock costs.

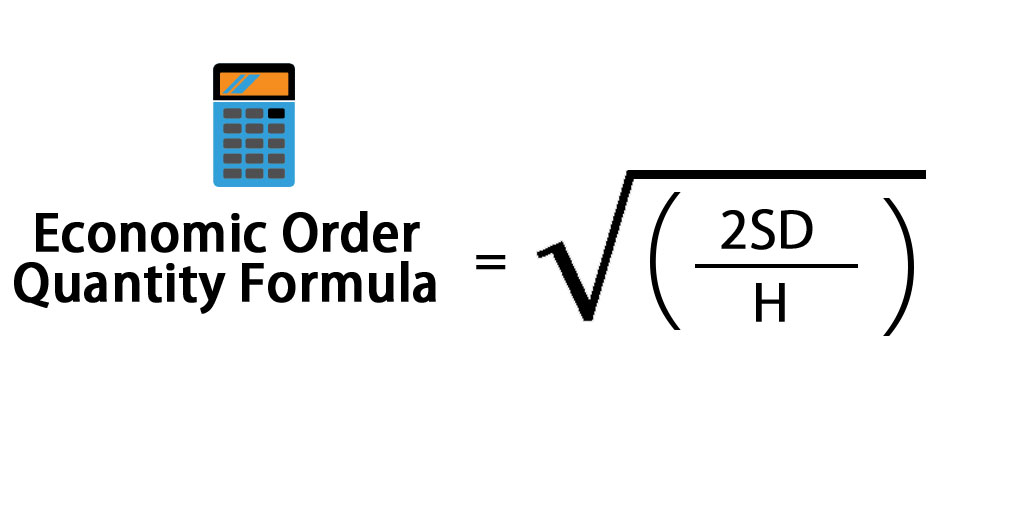

The EOQ formula is elegantly expressed as follows: EOQ = √[2(setup costs)(demand rate) / holding costs].

Cracking the EOQ Formula:

The EOQ Formula is elegantly expressed as:

- EOQ = √[2(setup costs)(demand rate) / holding costs]

Now, let’s break down the elements:

- Setup Costs: These are the expenses incurred each time an order is placed, encompassing activities like order processing, paperwork, and transportation. Reducing setup costs encourages more frequent ordering of smaller quantities.

- Demand Rate: This represents the rate at which your products are consumed or sold. The higher the demand rate, the more frequently you’ll need to reorder.

- Holding Costs: Also known as carrying costs, these include expenses associated with storing and managing inventory, such as storage space, insurance, and capital tied up in inventory. Holding costs typically increase with larger order quantities.

Unlocking Efficiency with EOQ:

Optimizing the EOQ empowers businesses with several advantages:

- Cost Savings: By identifying the ideal order quantity, you can minimize both setup costs and holding costs, resulting in substantial savings over time.

- Enhanced Warehousing: EOQ helps maximize warehouse space utilization by reducing the need for excessive stockpiling.

- Reduced Stockouts: Maintaining an optimal inventory level minimizes the risk of running out of stock, ensuring that products are available when needed.

- Mitigated Overstock Costs: Excessive inventory ties up capital and incurs additional costs. EOQ helps strike a balance, preventing overstock situations.

- Streamlined Operations: With EOQ in play, your ordering processes become more streamlined and efficient.

Practical Applications of EOQ Formula:

Applying the EOQ Formula and integrating it into your business’s unique variables necessitates a deep understanding of your integrated supply chain, It’s not a one-size-fits-all solution but rather a tailored approach to optimizing inventory management.

The EOQ formula finds practical application within Top Industries’ procurement and production departments, specifically for the development of pallet inverters.

EOQ Formula: Your Key to Optimizing Inventory Efficiency and Reducing Costs

Mastering the EOQ Formula is a strategic move for businesses seeking to optimize their logistics, reduce costs, and streamline operations. By finding the ideal order quantity, you can strike the perfect balance between inventory levels and expenses, setting your business on the path to enhanced efficiency and profitability in the world of supply chain management and PLC automation.