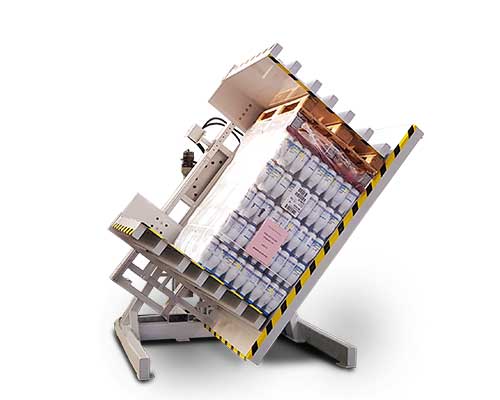

A pallet inverter is a valuable piece of equipment that can greatly enhance your material handling process. It is designed to rotate and reposition pallet loads, allowing for efficient pallet exchange, product repositioning, and accessibility to goods.

Factors to Consider for Optimal pallet inverter Placement

Proximity to Incoming and Outgoing Goods

One crucial factor to consider when positioning a pallet inverter is its proximity to incoming and outgoing goods. Placing the pallet inverter near the receiving dock can expedite the unloading process, enabling quick transfer and repositioning of goods. Similarly, positioning it near the shipping area ensures swift pallet exchange, facilitating faster loading and dispatching of products.

Accessibility and Workflow Optimization

Efficient workflow is vital for any facility, and the placement of a pallet inverter plays a significant role. It is recommended to position the pallet inverter in a central location that allows easy access for both operators and forklifts. This centralized placement promotes a smoother workflow, minimizing the time and effort required for transporting pallets and reducing the chances of congestion and bottlenecks.

Compare Pallet Inverter Models: Which One is Right for You?

Safety Considerations

Safety should always be a top priority in an industrial setting. When determining the placement of a pallet inverter, it is crucial to consider safety regulations and guidelines. Ensure that the chosen location allows sufficient space for safe operation and maintenance of the equipment. Clear pathways, adequate lighting, and proper ventilation should also be taken into account to create a secure work environment.

Are there any safety regulations that apply to the use of pallet inverters?

Integration with Existing Systems and Infrastructure

Evaluating Material Handling Processes

To optimize the placement of a pallet inverter, it is essential to evaluate your facility’s existing systems and infrastructure. Consider the integration with conveyor systems, racking, and storage areas. The placement of the pallet inverter should align with these systems to facilitate a seamless flow of goods.

Power Supply and Utilities

Additionally, consider the availability of power supply and accessibility to necessary utilities when deciding on the location of the pallet inverter. Ensure that the chosen placement can support efficient operation and functionality of the equipment.

Conclusion

Finding the best place to position a pallet inverter in your facility requires careful consideration of various factors. By understanding the role of a pallet inverter, evaluating proximity to incoming and outgoing goods, optimizing workflow, prioritizing safety, and integrating with existing systems, you can determine the most suitable location that maximizes efficiency and productivity.

At Top Industries Inc., we are dedicated to providing innovative pallet inverter solutions to optimize your material handling processes. Our team of experts can offer personalized recommendations on the ideal placement of a pallet inverter within your facility. Contact us today to learn more about our pallet inverter solutions and how we can help enhance your material handling operations.