One of the main problems in the world of pallet changers is the lack of knowledge of the product itself and the existence of a market that deals only with the handling of products in the warehouse, one of the most delicate activities in all logistical processes.

Within this article, the goal is to shed light: on the internal operational needs of large and medium-sized companies.

On the advantages deriving from the exploitation of pallet changing machines, and finally on the existing and patented technologies available in the Top Industries production range.

Why change the pallet?

At Top Industries we always talk about innovation, patented systems, attention to people, and many other values that are part of tradition. Today, the intention is to reverse this trend by speaking more generally of the products belonging to the production range to involve and spread the knowledge deriving from the experience of more than 40 years in the sector with all our readers to promote sharing.

First of all, we always talk about pallet changers, but not everyone knows what its real use is.

The pallet change operation is very simple and consists of transferring a load from one pallet to another and this, in addition to taking place in many ways, can take place for various reasons:

- Hygienic-sanitary reasons (change from wooden pallets to plastic pallets)

- Upon exiting the “white areas” to change the pallet from plastic to wood

- To save on the costs of shipping pallets

- To automate the operation done manually by the operators

- To replace broken pallets

- To replace broken products

The operation we deal with is typical of medium and large companies, but this does not prevent small companies that handle even a few pallets a day from contacting us as first of all, the gain is in terms of time.

The load of a pallet can reach very high weight thresholds that make moving the products tiring, slow, and imprecise. This subsequently involves a more complicated storage and with problems of permanence in the warehouse of the products that are difficult to manage and unforeseen.

Therefore, changing the pallet, moving the load from one pallet to another, is no longer an operation that can be done manually by the human being as well as for the reasons listed above, also for: the high levels of stress caused to the operators, the load physical work and above all to reduce waste of time.

With any machine for changing the pallet, an operation of 30-60 minutes has a duration ranging from 40 seconds for the fastest machines up to 5 minutes for standard and less technological pallet changes.

As we have seen, it is essential to change the pallet, not only to save costs or for hygiene issues particularly at the heart of companies, but for real legislative obligations, consequently it is a crucial operation.

A further source of importance of the activity depends on the ever increasing development of fully automated warehouses which therefore manage all incoming and outgoing goods without the aid of manpower. The machines, however, are not human beings, this entails the need for absolute precision in the mandatory pallet change phase which becomes the most delicate activity of the entire production process.

As you can see, depending on the need, it is necessary to have machines equipped with completely different levels of technology in order to satisfy both the small company with less need for intervention, and the large multinational with the need for highly customized systems.

For this reason, the production range of a leading company in the sector such as Top Industries cannot be limited to a few units and therefore little flexibility in choice. It must be broad in order to offer solutions that are as close as possible to the needs of the market players. Consequently, the current range boasts over 50 products with different technologies, some of which are patented.

Advantages of using a pallet changer

We have already mentioned the savings in terms of time required by the operators to complete the operation, but it is not the only advantage in using these machines. In fact, not everyone knows that not all geographical areas of the world use the same type of pallet, but there are different ones. Working, especially in automatic warehouses, with different types of pallets is impossible for a machine or at least it becomes very difficult to program it in the best possible way. With a machine capable of quickly replacing the pallet, however, this problem does not arise.

There is also an economic issue linked to this. In fact, not all pallets have the same production cost, but there are different qualities. It is the concern of each company to be able to minimize costs and therefore the cheapest possible pallet is used for transport according to the needs of the company that will receive the product. In this way, in a few minutes for each operation, large multinationals are able to save hundreds of thousands of dollars and this consequently justifies the birth of our market segment.

Using a pallet changer therefore we have savings in terms: economic due to the lower cost of the pallets shipped and the greater efficiency of labor; and time spent on individual operations. Furthermore, it is also possible to quickly manage extraordinary unforeseen events such as the breakage of a pallet or a single product without this completely blocking production, causing delays and therefore dissatisfaction in the end customer.

Also not to be underestimated are the incidence of accidents in the workplace and the stress threshold, already mentioned, which are literally reduced as there is no physical effort required by the operator. This leads to a safeguard of physical integrity, but also a greater productivity which corresponds to a perception of greater usefulness which increases the motivation of the operators.

The use of these machines therefore improves the processes in all aspects of the production activity both from a purely economic-business point of view, and from the personal point of view of the worker.

How a pallet changer works: technologies and peculiarities

At this point, after explaining the function of the pallet changer, its usefulness and the advantages of use, the time has come to actually explain how this machine works.

Only in the Top Industries production range are all the technologies that can be used for the operation present at the same time, including the most innovative patented and exclusive solutions.

In detail, the usable operations depend primarily on the product to be handled. Leaving aside for the moment the physical characteristics such as weight, height and type of packaging for simplicity, the macro-types can be two: tipping or non-tipping products.

The tipper products are the least problematic to handle because they can be processed with the use of all the technologies available on the market, including the tipping of the entire load. This technology was first invented by engineers more than 20 years ago and is the most popular technology on the market due to its simplicity. The machine then, according to different systems based on the technical specifications, blocks the load, lifts it and tilts it to specific gradations to allow the operation.

Another technology reserved for tipper products is load rotation. The operation, however, is similar to the previous one. In fact, in this case the load is rotated to a defined angle which can be 90 ° or 180 °, at this point the pallet is removed and the new one inserted, and finally everything is brought back to the starting position.

As an alternative to overturning and rotation, there are other technologies:

- Pushing

- Side shifting

Pushing is the first technology that does not tip the load; therefore, any type of product can be handled in this way. The products are then gently pushed from one pallet to another so that even the most fragile products can be handled. The main peculiarity is the sliding of the products from one pallet to the next in a rapid and risk-free manner.

As said initially, however, Top Industries has patented technologies and in this case it is essential to highlight it. The range of production includes the Easy Changer which totally changes the way of interpreting technology. In this pallet changer it is not the product that slips, but the pallet itself. The product is then raised slightly through two side pressers and the new pallet is inserted, pushing out the old one which is automatically stacked by the machine itself.

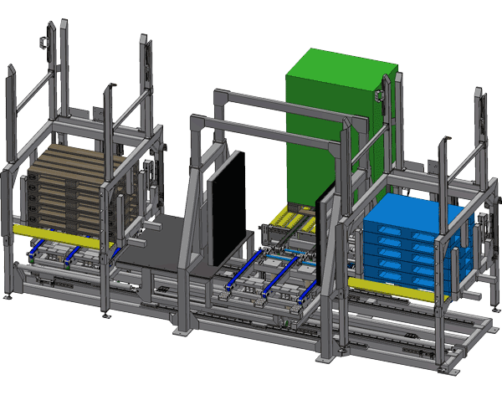

Finally, there are the side shift pallet changers. Through this technology it is possible, in addition to replacing the pallet, also to separate and divide the load on several different pallets.

Once again, in these machines, there are pressers that block the product, lift it slightly and, this time, move it laterally on the new pallet, finally releasing the products.

Also in this case the product is not overturned and the gentle pressure allows you to handle fragile products without any risk. Following the line of patented pallet inverter, however, it is necessary to expose the differentiating characteristic of the Falcon Wings. This machine adds even more stability to the load for stacks of very heavy products for which lateral pressure is not sufficient. To overcome this, two blades have been inserted that are placed at the base of the load through a controller. The task performed is merely to support the battery during the operation.

At this point the technologies currently on the market are exhausted. However, there are other differentiating factors on the market based on the characteristics of the machine:

- Mobile pallet changer

- Stationary pallet changer

- Fully automated pallet systems

None of these types, however, can ignore the exploitation of one of the technologies listed above.

We have reached the end of the blog. This was the main information any user needs to start looking for a product in this market. Summarizing the main concepts, the purposes of use and the related improvements both in the production process and in the economy, as well as the existing technologies, were explained.

By following this information you will be able to better orient yourself in the sector, managing to precisely build your needs and the advantages you can achieve to obtain a competitive advantage.