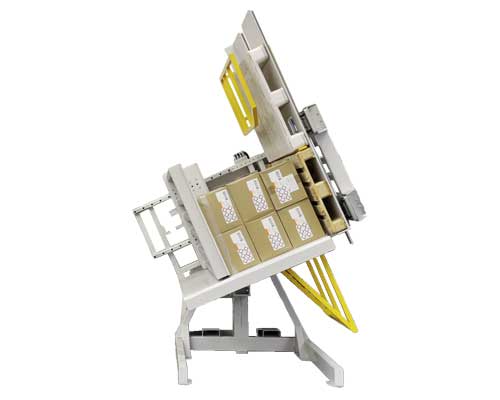

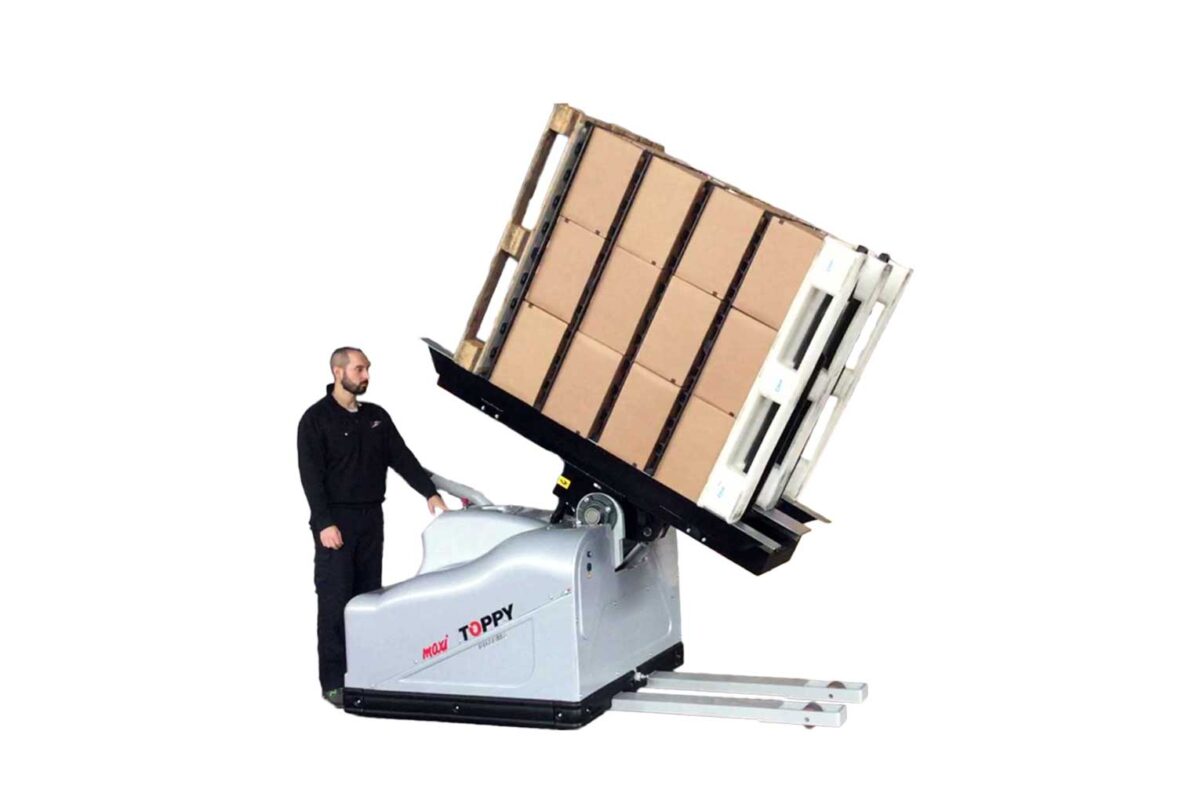

A pallet turner is a valuable piece of equipment that helps you turn over heavy pallets with ease, saving you time and energy. However, like all machines, pallet turners require regular maintenance to ensure they continue to function properly and last for a long time

Importance of Regular Maintenance

Proper maintenance of your pallet turner (learn more) is essential to keep it in good working condition. Neglecting maintenance can lead to costly repairs or even replacement of the equipment. Regular maintenance can also prevent accidents and injuries, as well as reduce downtime, ensuring that your operations run smoothly.

Cleaning Your Pallet Turner

One of the most basic maintenance tasks is cleaning your pallet turner. Regular cleaning can prevent dirt and debris from building up and causing damage to the machine. To clean your pallet turner, first, turn it off and unplug it. Use a soft cloth or brush to remove any dirt or debris from the machine, paying particular attention to the moving parts. You can also use a mild cleaning solution to wipe down the surfaces, but be sure to follow the manufacturer’s instructions and avoid using harsh chemicals that could damage the machine.

Lubricating Moving Parts

Lubricating the moving parts of your pallet turner is another important maintenance task. Lubrication reduces friction and wear, preventing damage to the machine. To lubricate your pallet turner, refer to the manufacturer’s instructions to identify the parts that require lubrication and the type of lubricant to use. Apply the lubricant sparingly and wipe off any excess to prevent buildup.

Regular Inspections

Regular inspections of your pallet turner can help you identify potential problems before they become serious. Inspect the machine for signs of wear or damage, such as cracks, worn or broken parts, or loose bolts or screws. Check the electrical components, such as cords and plugs, for signs of damage or wear and replace them if necessary. Refer to the manufacturer’s instructions for the recommended inspection schedule and procedures.

Common Issues and Troubleshooting

Despite regular maintenance, your pallet turner may experience issues from time to time. Here are some common problems and troubleshooting tips:

Motor Not Working

If your pallet turner’s motor is not working, first check the power supply to ensure it’s properly connected. Next, check the electrical components, such as the cords and plugs, for signs of damage or wear. If the motor still doesn’t work, it may need to be replaced.

Pallets Sticking or Jamming

If your pallet turner is having trouble turning over pallets, it may be due to dirt or debris buildup on the machine’s surfaces or moving parts. Try cleaning the machine thoroughly and lubricating the moving parts. If the problem persists, check for worn or broken parts and replace them as needed.

Conclusion

Proper maintenance of your pallet turner is crucial for its longevity and optimal performance. Regular cleaning, lubrication, and inspections can prevent damage, reduce downtime, and ensure safe and smooth operations. By following these tips, you can keep your pallet turner in top shape for years to come.

If you have any questions about maintaining your pallet turner or need assistance with repairs or replacement, contact Top Industries Inc. Our team of experts can help you with all your pallet turner needs.