Freezer Spacers Insertion & Removal Machines

Freezer Spacers Insertion & Removal Machines are advanced systems engineered to automate the placement and extraction of plastic freezer spacers during blast freezing and thawing operations. Available in mobile models and stationary models, these machines adapt to different production needs and facility layouts. Mobile units are compact, versatile, and easy to move around the warehouse, making them ideal for companies that require flexibility in different working areas. Stationary systems, on the other hand, are designed for high-throughput environments, often integrated into conveyor lines or fully automated cold storage facilities.

These machines are widely used in the food industry—particularly in meat, poultry, seafood, bakery, and dairy processing—as well as in pharmaceutical cold chains, where hygiene, speed, and temperature control are critical. By automating spacer insertion before freezing and removal afterward, businesses can achieve faster pallet turnaround, reduced labor costs, improved worker safety, and consistent product quality. Whether mobile or fixed, freezer spacer machines deliver a reliable and efficient solution that supports modern cold-chain logistics.

Freezer Spacers Insertion & Removal Machine L-Shape Splitter

Stationary version that assists the operator with the insertion and removal of freezing spacers.

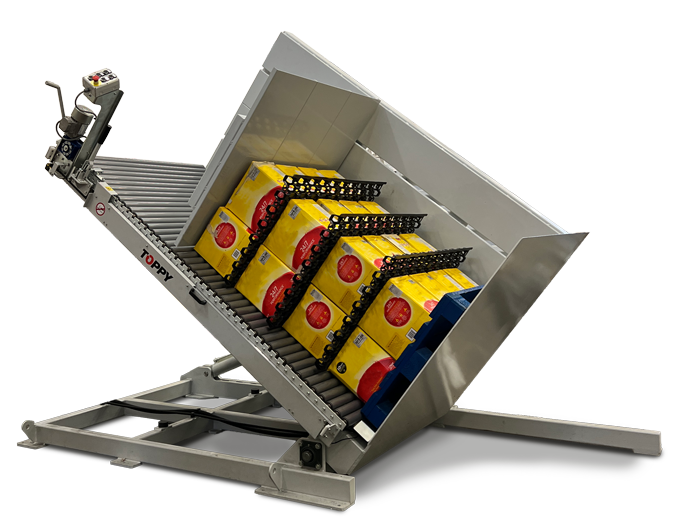

Freezer Spacers Insertion & Removal Machine Turner 3300

A mobile device that assists the operator with the removal

of freezer spacers

Why Our Freezer Spacers Insertion & Removal Machines Lead the Market

At Top Industries Inc., freezer spacer systems are not just machines – they are the result of decades of engineering expertise, innovation, and close collaboration with cold-chain operators. Whether you need a mobile unit for flexible operations or a stationary system for high-throughput environments, our freezer spacers insertion & removal machines are designed to maximize efficiency, enhance worker safety, and ensure consistent product quality.

Types of Freezer Spacers Machines

Mobile Freezer Spacers Machines

Mobile models are compact and easy to move around the facility. They provide flexibility, making them an excellent solution for medium-size companies or operations where spacer handling is needed in multiple areas. A mobile machine can be relocated depending on production peaks, seasonal demand, or workflow changes.

-

Advantages: mobility, lower investment compared to stationary units, adaptable to different working zones.

-

Best suited for: companies seeking versatility without fully redesigning their production flow.

Stationary Freezer Spacers Machines

Stationary models are fixed installations, usually integrated into automated lines. They are ideal for high-throughput environments where pallets must be processed continuously with minimal downtime. These systems are often connected to conveyors, palletizers, or robotic lines, ensuring seamless operation in large food processing plants, pharmaceutical facilities, and cold-storage warehouses.

-

Advantages: highest speed, minimal labor, fully automated cycles, scalable to large volumes.

-

Best suited for: industrial-scale operations requiring 24/7 reliability.

Use Cases Across Industries

Food Industry

Freezer spacers machines are widely used in meat, poultry, seafood, dairy, and bakery sectors, where rapid and uniform freezing is crucial to maintain product safety and shelf life. Automating spacer handling ensures hygienic operations while reducing damage to delicate packaging.

Pharmaceutical Sector

In pharmaceuticals and biotech, cold-chain management is critical for products like vaccines, enzymes, and temperature-sensitive drugs. Spacer machines ensure that pallets can be frozen or thawed quickly and under strict sanitary conditions, reducing human contact and risk of contamination.

Cold Storage and Logistics

3PL providers and cold warehouses benefit from spacer machines as they speed up pallet turnover, reduce labor dependency, and standardize freezing processes. Both stationary and mobile solutions can be scaled according to facility size and workload.

Key Benefits

-

Efficiency: faster spacer insertion and removal drastically reduce freezing and thawing cycle times.

-

Safety: automation eliminates heavy manual lifting, minimizing workplace injuries.

-

Consistency: uniform handling guarantees product quality and reduces packaging damage.

-

Cost savings: lower labor needs and increased throughput lead to better ROI.

-

Compliance: machines support strict hygiene standards required in food and pharmaceutical industries.

Buying Criteria for Freezer Spacers Machines

When evaluating the right system for your facility, consider the following factors:

Throughput Requirements

High-volume facilities processing hundreds of pallets daily should invest in stationary machines, while smaller or more flexible operations may benefit from mobile units.

Facility Layout

If your warehouse has a fixed automated line with conveyors, a stationary system offers the best integration. For facilities with multiple freezing areas, a mobile model provides versatility.

Budget and ROI

Stationary machines require higher initial investment but deliver significant long-term cost savings through automation. Mobile machines, meanwhile, offer faster payback for mid-scale businesses.

Maintenance and Support

Choose a provider that offers comprehensive after-sales service, spare parts availability, and operator training to ensure long-term machine performance.

Finding the right machinery

for you in 3 steps

We have a customer-focused approach that enables us to prioritize their needs with a dedicated offer creation process.

Start NowGet in touch with our experts

STEP 1

Answer the questionnaire

We provide you with a questionnaire asking for details about your operational needs, such as the type of product you handle. This helps us understand how we can assist you.

STEP 2

Our consultants will find the best solution for you

Through the information you provided, our consultants will analyze your information to build a customized offer based on your needs choosing among over 50 different pallet changer models.

STEP 3

Boost your production processes

With our tailored solutions, you can significantly boost your productivity by choosing a system that perfectly aligns with your specific needs and operational goals.

Suitable for every brand,

including yours

Our freezer spacers insertion & removal machines are trusted by leading cold-chain operators to keep products safe and operations efficient. Designed for both mobile flexibility and stationary high-throughput environments, these systems eliminate the challenges of manual spacer handling, ensuring faster pallet turnaround and consistent freezing performance.

Companies across the United States and worldwide—from food distributors like US Foods to global cold-storage leaders such as Americold—rely on this technology to optimize workflows, improve worker safety, and maintain strict quality standards in frozen logistics. By automating spacer insertion before blast freezing and spacer removal afterward, our machines reduce labor dependency, minimize packaging damage, and guarantee compliance with demanding hygiene regulations.

Why Choose Top Industries Inc.

As a U.S. leader in freezer spacers insertion & removal systems, Top Industries Inc. combines advanced engineering with decades of cold-chain expertise. Backed by more than 36 patented solutions and the long-standing innovation of our parent company Toppy, we deliver equipment designed to match the specific needs of food processors, pharmaceutical companies, and logistics providers. Whether you need a mobile unit for flexible operations or a stationary automated system for high-volume throughput, Top Industries offers the most reliable and innovative machines to optimize your freezing and thawing processes.

Leading the USA

in pallet changing solitions

We stand out with our range of over +36 patented pallet changer models, offering tailored solutions to fit various products, workflows, and spaces, making us the leading choice for American companies.

Choose The USA LeaderGet in touch with our experts

+36 PATENTED SOLUTIONS

Freezer Spacers Insertion & Removal Machines – FAQ

What is a freezer spacers insertion & removal machine?

It is an automated system designed to place and remove plastic spacers between pallet layers during blast freezing and thawing. This process ensures faster and more uniform freezing while eliminating heavy manual labor.

What types of machines are available?

Top Industries Inc. offers two types:

-

Mobile machines, compact and easy to move across different freezer zones.

-

Stationary machines, fixed units designed for high-throughput facilities with automated conveyor lines.

Which industries benefit the most?

They are widely used in the food industry (meat, poultry, seafood, bakery, dairy), pharmaceuticals, and cold storage logistics, where hygiene, speed, and consistent product quality are critical.

What are the main benefits of automation?

-

Faster pallet turnaround

-

Reduced labor costs

-

Improved worker safety

-

Consistent freezing and thawing performance

-

Compliance with hygiene and cold-chain standards

How do I choose between mobile and stationary models?

The choice depends on your throughput needs and facility layout. High-volume operations with automated lines benefit from stationary systems, while companies requiring flexibility across multiple areas often prefer mobile units.

Do these machines integrate with existing systems?

Yes. Stationary machines can be seamlessly integrated into conveyors, palletizers, and warehouse management systems, ensuring smooth workflows and maximum efficiency.

Is there a step-by-step guide available for using your machines?

Yes, we have created a tutorial specifically for our clients to help them quickly learn how to use the stationary model for freezer spacer insertion and removal. Here’s the link to the video on YouTube!