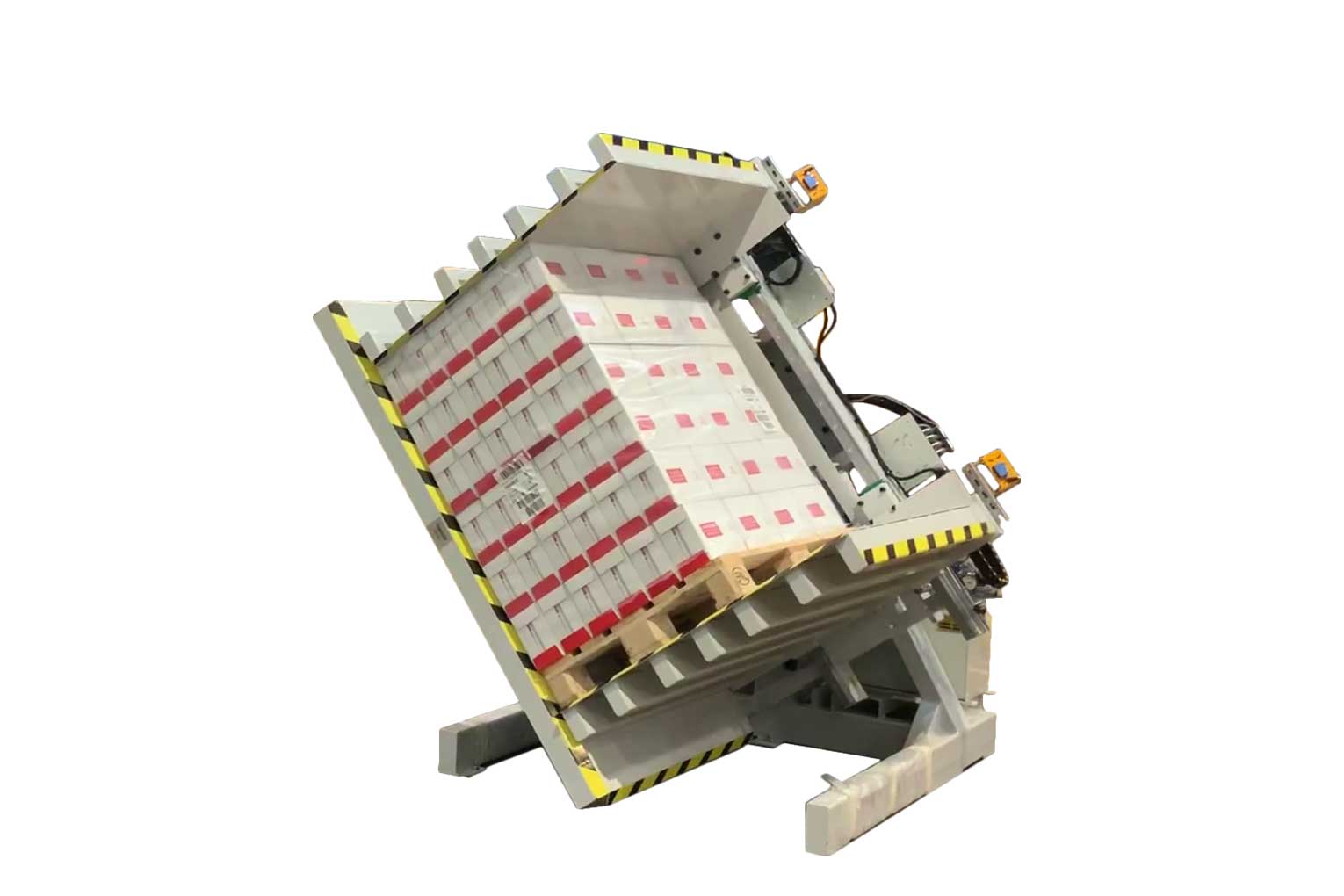

This is the classic fixed pallet inverter originally designed by Toppy. Discover also the cutting-edge technology of the latest edition: the advanced pallet turner!

Also available in a mobile version

Semi-automatic system;

Easily turn about 35 pallets – hour

Load capacity of up to 3300 lbs

Images for Fixed Pallet Inverter

Cycle Description

Cyle Description of Pallet Inverter

This solution is part of the pallet inverter family.

The pallet inverting process involves the following steps:

- Place the pallet load on the machine using a forklift.

- Secure the load from the top with a movable platform.

- Invert the entire load 180° so that the pallet moves above the load.

- Move the platform down to create space between the inverted load and the fixed platform.

- Replace the pallet if necessary or replace damaged products from the bottom.

- Move the platform up to secure the load again.

- Invert the load 180° to return it to its original position.

- Separate the movable platform from the load.

- Stack or load the pallet.

- For less stable products, turn the load 90°.

Your safety is our priority

Businesses trust TopIndustries Inc because we pay equal attention to efficiency and safety. This inverter comes with all the safety features in place to ensure injury-free operations. Features like safety photocells, metal perimeter protection, and fence nets help the operators to perform tasks without the fear of getting injured.